TM 5-3895-376-14&P

5-17. GOVERNOR ASSEMBLY MAINTENANCE INSTRUCTIONS

This task Includes:

a. Adjust

d. Inspection

b. Remove

e. Repair

c. Cleaning

f. Installation

INITIAL SETUP

Tools

Equipment Condition

Tool Kit, General Mechanic's

Compactor set on level ground in a protected area.

Tachometer, Mechanical; item 44, Appx F

Engine off.

Wrench, Torque; item 50, Appx F

Oil Drained.

Materials/Parts

General Safety Instructions

Grease, Automotive and Artillery; item 4, Appx E

Observe all WARNINGS and CAUTIONS

Solvent, Dry Cleaning; item 9, Appx E

Loctite Compound; item 5, Appx E

Spring set, (1)

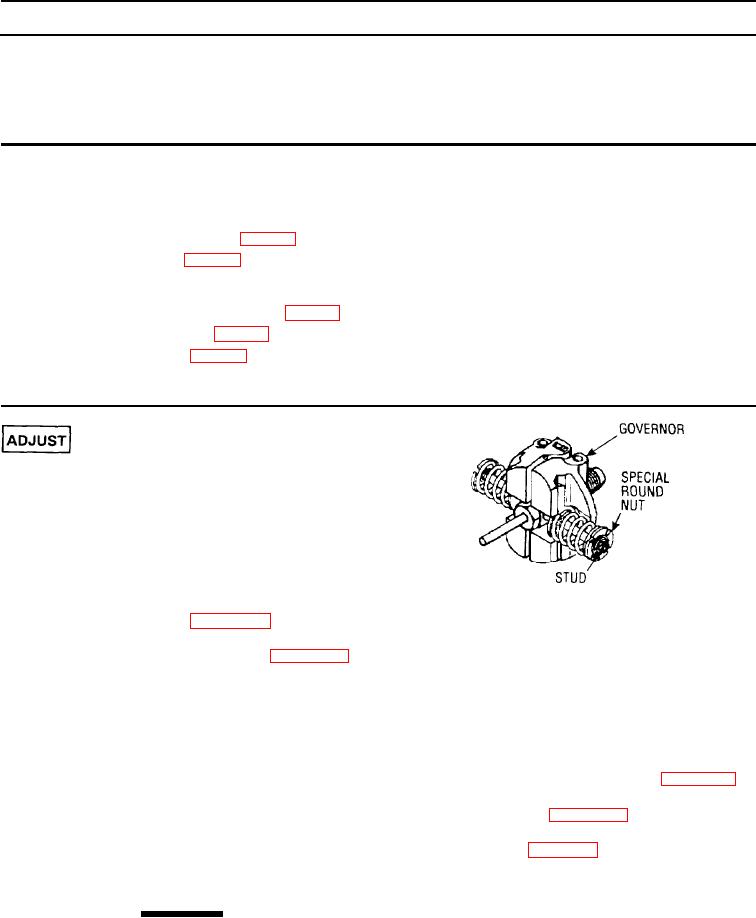

NOTE

Adjustment of the governor is only re-

quired after repair of the governor, such as

replacement of the governor spring set,

and is a long process. Adjustment of the

governor is limited to approximately a 50

rpm speed range.

1.

Remove the v-belt cover (Para. 4-24).

is not fully engaged with the stud of

2.

If necessary, remove the gear cover (Para. 5-14).

governor, nut may vibrate loose with

other parts causing internal damage

NOTE

before shutdown.

Adjust both special round nuts the same

To provide decrease in governed speed, loosen

4.

amount, to distribute load evenly on the

the special round nut.

spring set. Access to special round nuts

may be made through openings of inspec-

If removed, reinstall the gear cover (Para. 5-14).

5.

tion cover, fuel pump or compression re-

lease.

Service the engine (Para. 4-12).

6.

To provide increase in governed speed, tighten

3.

Start the engine (Para. 2-5) and move throttle

7.

the special round nut.

control to idle position.

CAUTION

8.

Using a hand held tachometer, held against the

hub of clutch, observe the engine speed both at

engine idle and at full load. Idle speed should be

Special round nuts must be at least

flush with end of governor studs. If nut

5-48