TM 5-3895-376-14&P

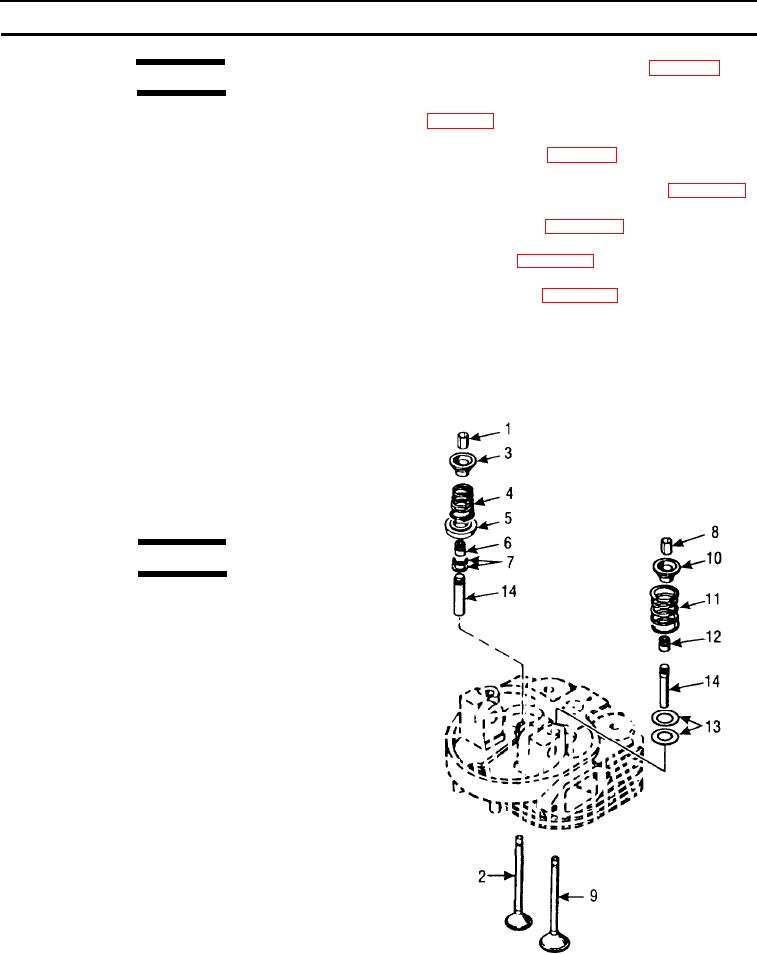

5-9. VALVES MAINTENANCE INSTRUCTIONS - Continued

4.

Install the cylinder head assembly (Para. 5-8).

WARNING

5.

Install and adjust rocker arms and push rods

Valve springs and collars are under

spring tension and can act as projec-

tiles when released and could cause se-

6.

Install fuel injector (Para. 5-4).

vere eye injury. Eye protection is

required.

7.

Connect fuel lines to the fuel injector (Para. 4-29).

d.

Install intake valve spring (11) and spring col-

8.

Install valve cover (Para. 4-33).

lar (10). Compress the spring and retainer us-

ing the valve spring lifter, sufficiently to allow

9.

Install muffler (Para. 4-31).

installation of the valve spring retainer (8). In-

ternal shoulder of the retainer halves must en-

10. Install air cleaner (Para. 4-27).

gage the notch of the valve stem, then

remove the valve spring lifter.

NOTE

Follow-on tasks include: Return compactor

2.

Install the exhaust valve (2) as follows:

to service.

a.

Install two washers (7), over the exhaust

valve guide.

b.

Install valve seal (6) on end of exhaust valve

guide.

c.

Install the exhaust valve (2), carefully feeding

stem through the valve seal (6).

WARNING

Valve springs and collars are under

spring tension and can act as projec-

tiles when released and could cause se-

vere eye injury. Eye protection is

required.

Install roto cap (5), exhaust valve spring (4) and

d.

spring collar (3). Ensure that large diameter end

of spring (4) is seated in the roto cap (5). Com-

press the spring and retainer using the valve

spring lifter, sufficiently to allow installation of the

valve spring retainer (1). Internal shoulder of the

retainer halves must engage the notch of the

valve stem, then remove the valve spring lifter.

3.

Check seating of valves in valve seats on bottom

of cylinder head. New valves must seat 0.098 -

0.102 in. (2.500 - 2.600 mm) below the bottom

face of the cylinder head. Remove a valve that

does not seat to this dimension, grind the valve

as necessary and reinstall.

5-22