TM 5-3895-376-14&P

5-20. CRANKSHAFT MAINTENANCE INSTRUCTIONS - Continued

Then slowly turn the flywheel one-quarter turn to

free crankshaft journal from connecting rod.

10. Remove the flywheel (Para. 4-37).

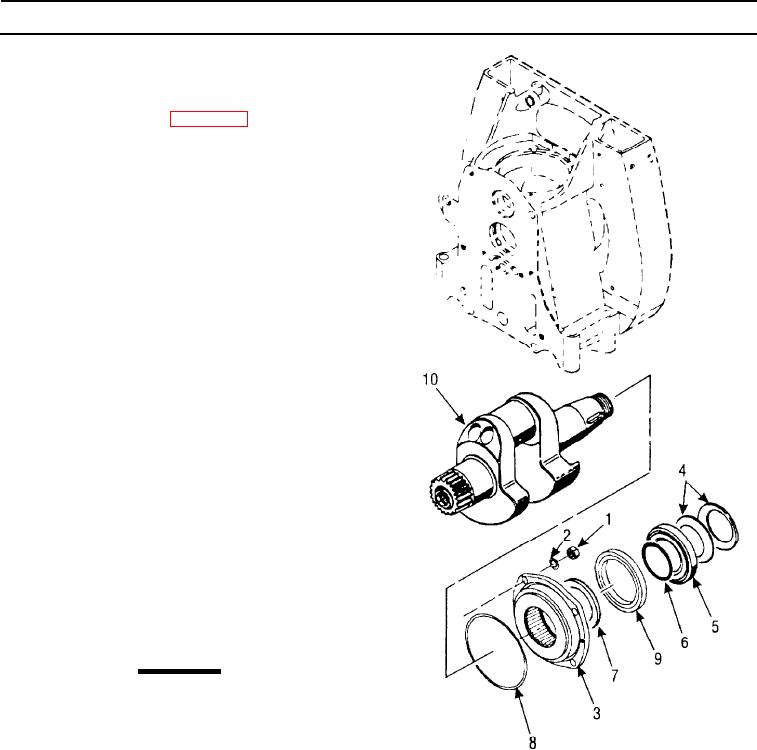

11. Remove four nuts (1) and lockwashers (2) that

secure seal housing (3).

12. Install two capscrews (Metric size M6 x 30 mm

long) in the two threaded holes in flange of seal

housing (3). Turn in the capscrews alternately un-

til the seal housing breaks free from the engine

housing.

13. Remove the two belleville washers (4), angle

ring (5), preformed packing (6) and thrust

washer (7). Discard the preformed packing.

14 Remove the seal housing (3) from end of crank-

shaft (10). and remove preformed packing (8)

from inner shoulder. Discard the preformed pack-

ing.

15. Pull or pry the encased seal (9) from the seal

housing (3). Discard the encased seal.

NOTE

Do not remove retaining ring or bearing

from seal housing (3). The Bearing inner

race is shrink fitted to the crankshaft and

must be replaced at general support main-

tenance.

CAUTION

Do not allow crankshaft gear to drag on

the front main bearing, installed in the

engine housing. Scoring of the bearing

will occur, requiring replacement of the

bearing.

15. Carefully remove the crankshaft (10) from the en-

gine housing.

5-57