TM 5-3895-376-14&P

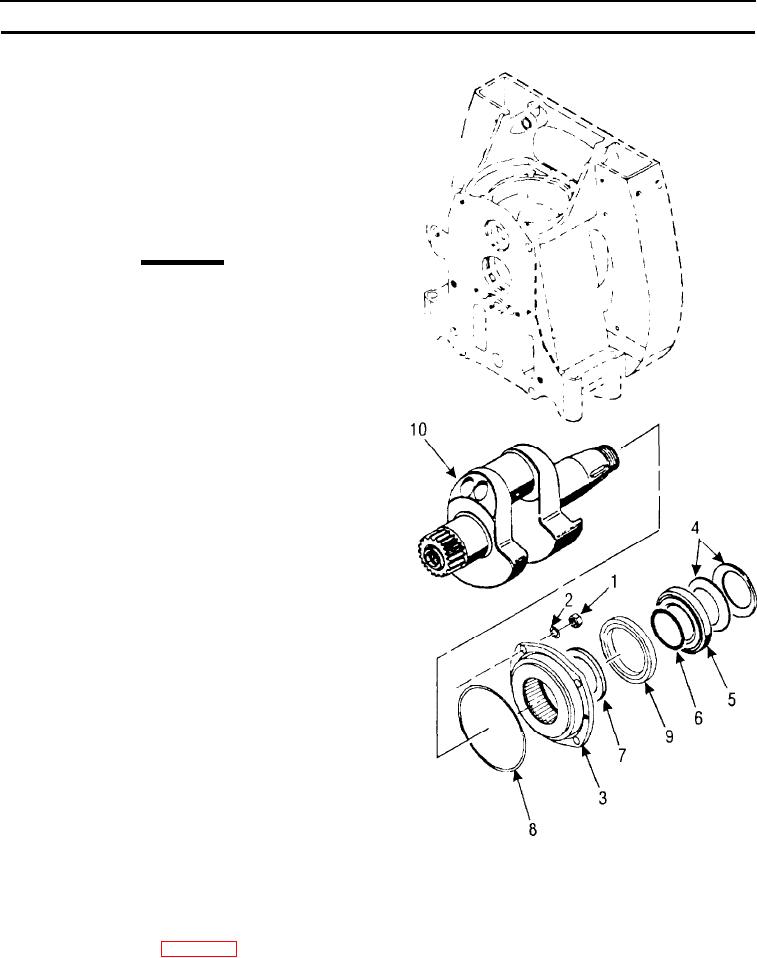

5-20. CRANKSHAFT MAINTENANCE INSTRUCTIONS - Continued

O.D. x 2.5 in. (64 mm) I.D.). Press the seal in

flush with face of seal housing.

3.

Turn seal housing (3) over. Coat preformed pack-

ing (8) with lubricating oil, and install on shoulder

of seal housing (3)

4.

Coat the front main bearing. Installed in engine

housing with lubricating oil.

CAUTION

Do not allow crankshaft gear to drag on

the front main bearing, installed in the

engine housing. Scoring of the bearing

will occur, requiring bearing replace-

ment.

5.

Carefully install the crankshaft (10) in the engine

housing, inserting crankshaft end journal into the

front main bearing.

6.

Coat the bearing race on crankshaft and lip of

seal (9), generously with lubricating oil.

NOTE

The seal housing 13) will only fit in one po-

sition, rotate housing as necessary to align

bolt holes with studs.

7.

Install seal housing (3) into engine housing, en-

gaging the inner race of bearing with rollers. Tap

gently around the seal housing with a plastic ham-

mer to seat the housing.

8.

Secure seal housing (3) with four lockwashers (2)

and nuts (1) Tighten nuts alternately until secure.

Torque to 22 - 25 ft-lbs (29 - 34 Nm).

9.

Coat the thrust washer (7). preformed packing

(6), and angle ring (5) with lubricating oil and in-

stall on the crankshaft (10). Ensure that the thrust

washer (7) is installed with markings side out and

angle ring (5) with cup side out.

10. Install one belleville washer (4) with dish facing

out, and the second washer (4) with the dish fac-

ing in.

11. install the flywheel (Para. 4-37).

5-60