39

7

18

17

18

17

TM 9-4940-568-34

5-143

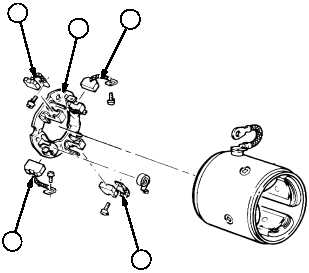

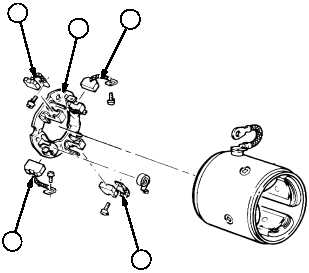

e.

Cleaning/Inspection.

Do not clean or immerse starter

motor parts in grease dissolving

solvents. Solvents will dissolve

grease packed in drive assembly

and may damage armature or

field coil insulation.

(1)

Clean all motor parts with a soft cloth prior

to testing.

(2)

Inspect all parts for cracks, distortion or

other structural damage. Replace parts or

assemblies which are cracked, bent or

otherwise damaged.

(3)

Inspect threaded parts for stripped, crossed

or otherwise damaged threads. Replace

parts with thread damage that cannot be

cleaned up. Replace any hardware items

that have damaged threads.

(4)

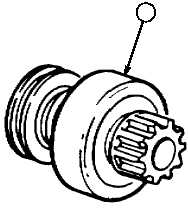

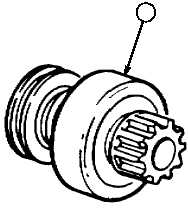

Inspect clutch drive assembly (39).

(5)

Replace clutch drive assembly if pinion gear

turns roughly or turns in both directions,

pinion gear teeth are broken or showing

evidence of step wear, and deep scoring or

other damage to shift lever collar has

occurred.

(6)

Inspect brush holder assembly (7). Replace

brush holder if loose riveted joints or

cracked or broken insulation is found.

(7)

Inspect brushes (17) and (18) for excessive

wear. The minimum allowable brush length

is 0.472 in. (12 mm). Replace excessively

worn brushes in sets.