TM 9-4940-568-34

5-141

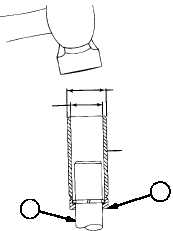

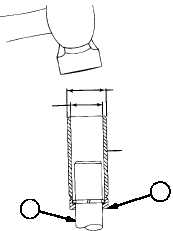

(8)

From inside of drive housing (12), drive out

bushing (36).

(9)

After all items in Step (1) through (8) have

been removed, perform cleaning and

inspection procedures.

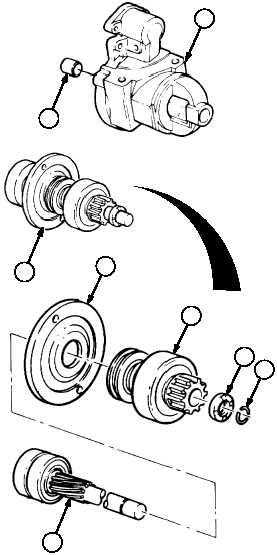

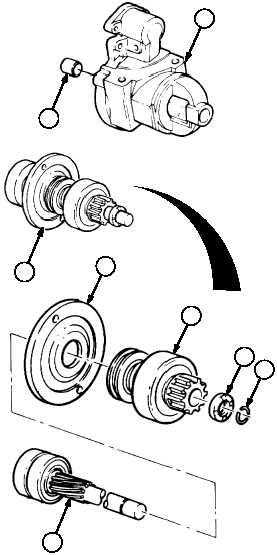

d.

Disassembly of Drive Shaft and Clutch Group.

NOTE

Disassembly of the drive shaft

and clutch group is not required

unless it is necessary to clean,

inspect, or replace one or more

parts of the group separately.

(1)

Position drive shaft and clutch group (25) on

work bench with internal gear end down.

(2)

Using an open tube slightly larger than the

drive shaft (37), drive pinion stop (38)

toward clutch drive assembly (39) until it

clears two stop rings (40).

(3)

Using care not to scratch drive shaft (37),

pry two stop rings (40) out of shaft groove

and slide off end of drive shaft (37).

Discard stop rings.

(4)

Inspect edges of shaft groove for burrs that

may have been formed through repeated

cranking cycles. Burrs may make removal

of pinion stop (38) and clutch drive

assembly (39) difficult. If burrs are found,

use a suitable file to carefully remove burrs

only – not base metal. Thoroughly clean

away metal fillings.

(5)

Slide pinion stop (38) off drive shaft (37).

Discard pinion stop.

(6)

Remove clutch drive assembly (39) from

drive shaft (37).

(7)

Remove drive shaft support (41) from drive

shaft (37).

12

41

36

40

14.2 MM

(0.56 IN.) DIA

22 MM

(0.87 IN.) DIA

OPEN

TUBE

37

38

25