Basic Engine

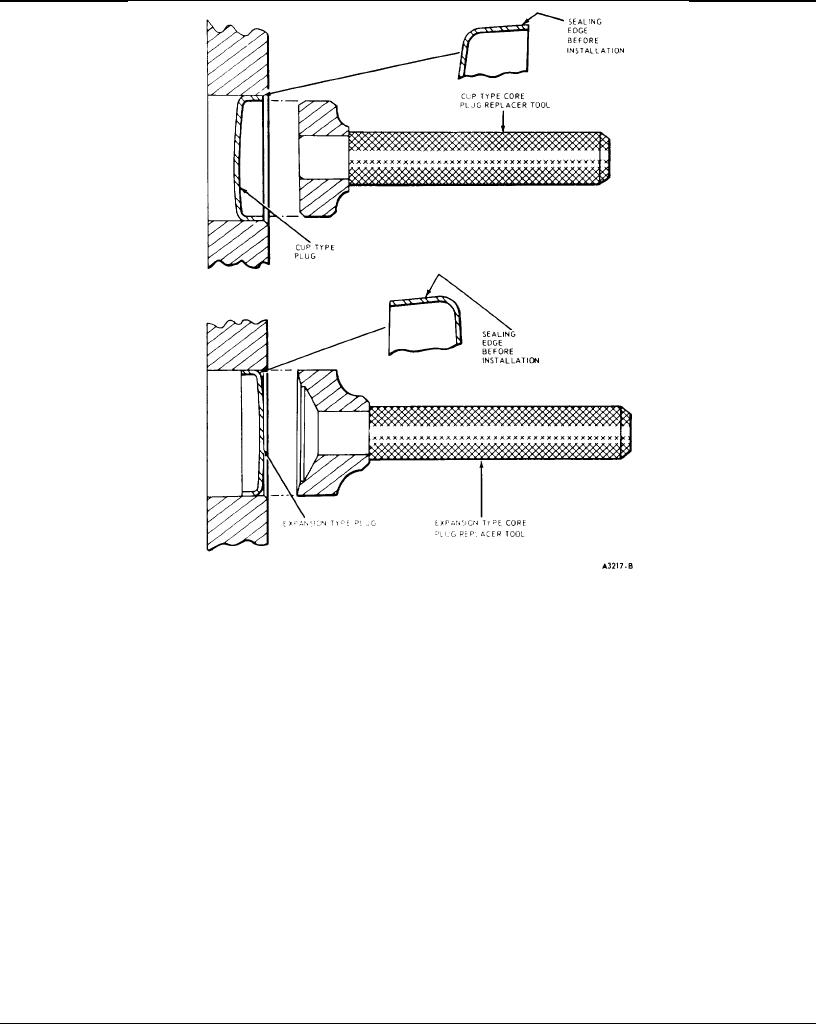

FIG 47. Core Plugs and Installation Tools - Typical

OIL PUMP

Installation

1. Clean the gasket surfaces of the block and oil pan.

Removal

Be sure to clean the seal retainer grooves in the

1. Remove the oil pan and related parts as outlined

cylinder block and oil pan. The oil pan has a two-

under Oil Pan Removal.

piece gasket. Coat the block surface and the oil pan

2. Remove the oil pump attaching bolts and remove the

gasket surface with oil-resistant sealer. Position the

oil pump. gasket, and intermediate drive shaft.

oil pan gaskets on the cylinder block (Figure 49).

Installation

2. Position the oil pan front seal on the cylinder front

1. Prime the oil pump by filling the inlet port with engine

cover. Be sure the tabs on the seal are over the oil

oil. Rotate the pump shaft to distribute the oil within

pan gasket.

the pump body.

3. Position the oil pan rear seal on the rear main bearing

2. Position the intermediate drive shaft into the

cap. Be sure the tabs on the seal are over the oil pan

distributor socket.

gasket.

3. Position a new gasket on the pump housing. Insert

4. Hold the oil pan in place against the block and install

the intermediate drive shaft into the oil pump. Install

a bolt. finger tight, on each side of the oil pan. Install

the pump and shaft as an assembly. Do not attempt

the remaining bolts. Torque the bolts from the center

to force the pump into position if it will not seat

outward in each direction to specifications.

readily. The drive shaft hex may be misaligned with

5. Install the oil level dipstick. Fill the crankcase with

the distributor shaft. To align, rotate the intermediate

the proper grade and quantity of engine oil. Operate

drive shaft into a new position. Torque the oil pump

the engine and check for oil leaks.

attaching screws to specifications.

4. Install the oil pan and related parts as outlined under

Oil Pan Installation.

1-23