Section IV. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

noted during operation which would damage the

4-6. General

equipment if operation were continued. All deficiencies

To insure that the earth auger is ready for operation at

and shortcomings will be recorded, together with the

all times, it must be inspected systematically so that

corrective action taken. on DA Form 2404 (Equipment

defects may be discovered and corrected before they

Inspection and Maintenance Worksheet) at the earliest

result in serious damage or failure The necessary

possible opportunity.

preventive maintenance checks and services to be

4-7. Preventive Maintenance Checks and Services

performed are listed as described in paragraph 4-7.

Preventive maintenance checks and services are listed

Defects discovered during operation of the earth auger

will be noted for future correction, to be made as soon

and described in table 4-1.

as operation has ceased. Stop operation immediately if

a

deficiency

is

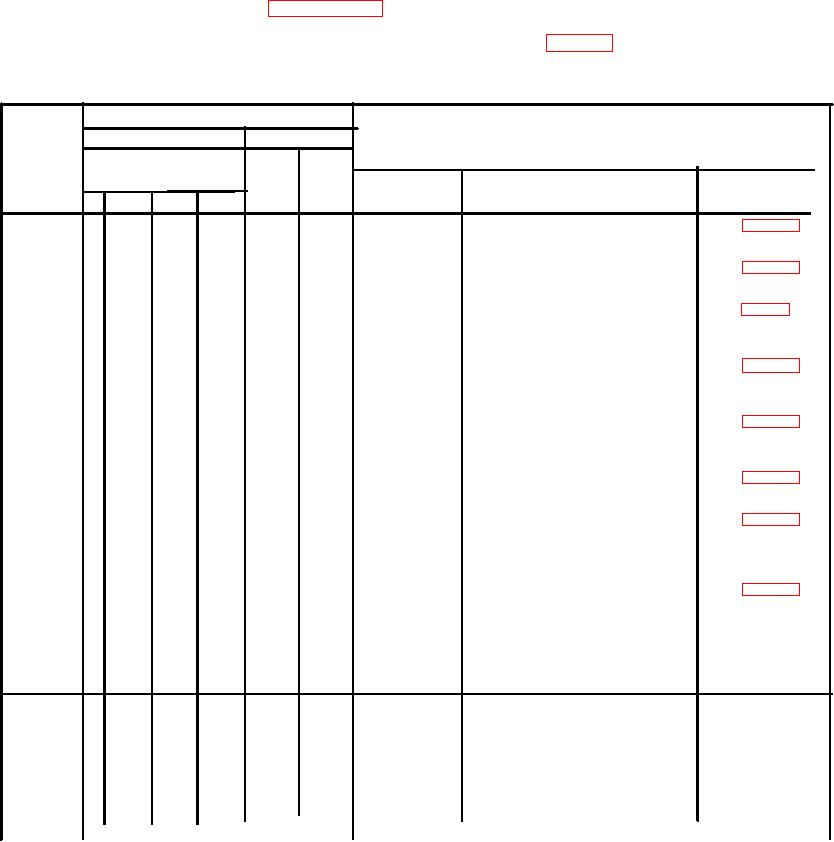

Table 4-1. Preventive Maintenance Checks and Services

Interval

B Before operation

A After operation

M Monthly

Operator

Org

D During operaton

W Weekly

Q Quarterly

Item

Daily

M

Q

Number

Item to be

Procedure

References

B

D

A

W

inspected

1

X

Muffler & pipes

if there are signs of corrosion or

excessive rust.

2

X

Cooling system

Test radiator cap pressure. If cap

pressure is below recommended

pressure, replace cap. Test thermostat.

X

Replace it' faulty. Inspect thermostat

(para 4-1 7)

housing for leaks. Replace gasket If

required. Inspect all coolant hoses

X

for leaks.

3

,

X

Fan belt

Inspect fan belt. Replace badly worn

or frayed belt. Adjust as required.

4

X

Fan blade

Inspect for damage. If there are signs

(para4-16)

of damage, replace the fan blade.

5

X

Hydraulic system

Inspect and service strainer and filter.

Replace it' necessary. Inspect all

hydraulic hoses. Replace any worn or

broken hoses.

6

X

Hydraulic pump

Inspect pump. Replace pump if

inoperative or it' it produces insufficient

results.

7

X

Control valve

Inspect and adjust control valve. Replace

if necessary

8

X

Hydraulic motor

Inspect motor for defective condition

(para 4-22)

or unsatisfactory operation. Replace

defective motor.

9

X

Hydraulic reservoir

Inspect for insecure mounting. Inspect

tank for damage or deterioration.

Service breather cap. Replace tank

or cap It' necessary.

10

X

Engine

Inspect engine for damage. leaks, or

(4-31, Also Ford

unsatisfactory conditions. Service as

Maintenance/Service

required. Inspect engine support for

Manuals)

insecure mounting. Inspect crankcase

breather or cap. Replace if defective.

11

X

Valves and cover

Inspect valve cover for damage or leaks

(Ref. Ford Maintenance

Replace if not serviceable. Check

/Service Manuals)

gasket for cracks or breaks.. Replace

if defective. If noisy or loss of power

is noticed, make valve adjustments in

accordance with (Ford Maintenance

/Service Manuals).

4-2