Section V. OPERATOR MAINTENANCE

drain and refill the fuel tank. Check for any obstructions

3-7. General

in fuel lines.

This section contains maintenance instructions that are

to be performed by the operator.

3-10. Transmission

a. Check level of lubricant in transmission by

3-8. Cooling System

removing cap level indicator located on the

a. Remove the radiator cap and check the level of

transmission.

coolant.

b. If level indicates low, add lubricant per Lube

b. Add coolant until level is approximately one inch

diagram until the level reaches full.

below neck of radiator.

c. Always use clean fluid and clean containers.

c. If there are signs of dirt or rust in the coolant,

d. Do not overfill.

drain and flush the cooling system as follows:

e. If the oil appears contaminated, remove the

(1) Remove the radiator cap to facilitate

drain plug and drain the oil. Refill with clean fluid.

(2) Open the coolant drain cock at the bottom

f. If the fluid has become contaminated with metal

of the radiator and allow the coolant to drain into a

particles, do not operate the equipment.. Refer to

suitable container.

higher level of maintenance.

(3) Fill the radiator with coolant as required

for lowest expected temperatures and attach a tag

NOTE

specifying the coolant used.

Stop engine before checking or adding

(4) Refer to paragraph 2-8 and start the

fluid Drain dirty fluid while unit is still

engine and allow it to operate until normal operating

warm

temperature is reached

(5) Refer to paragraph 2-9 and stop engine.

3-11. Engine

(6) Check coolant level. Add coolant as

a. Check crankcase oil level on indicator.

necessary.

b. If oil level is low, add oil specified in Lube

d. In cold weather operation, test the specific

diagram to full level. If there are signs of oil leakage or

gravity of anti-freeze. Add anti-freeze as required for

excessive oil consumption, refer to higher level of

lowest temperature expected.

maintenance.

e. If loss of coolant occurs, check for any leaks

and refer findings to higher level of maintenance for

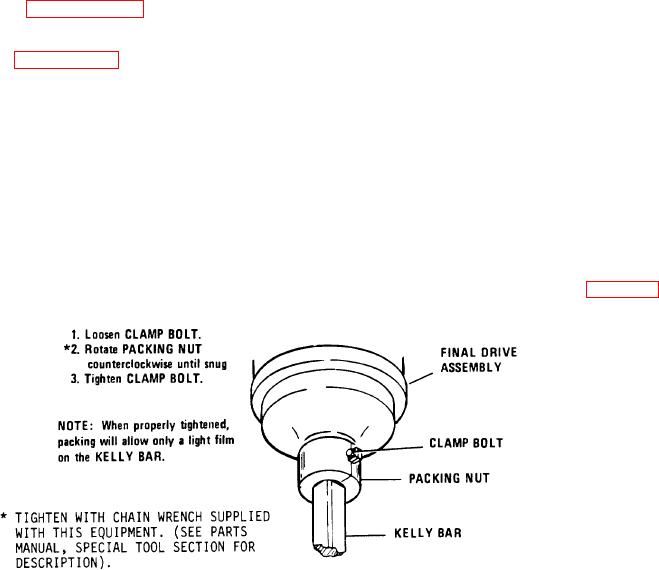

3-12. Kelly Bar (Lower) Packing Nut

repair.

a. After initial operation, the kelly bar packing nut

will tend to leak somewhat. Therefore, the nut must be

3-9. Fuel System

tightened in such a manner that the "leakage" leave only

a. Remove fuel tank cap. Inspect vent hole and

a "film" of hydraulic oil on the kelly bar. The nut must

remove any obstructions.

not be tightened to the extent that the kelly bar is dry

b. Fill fuel tank to capacity.

*b. To tighten the packing nut, refer to figure 3-1.

c. If evidence of fuel contamination is observed,

Figure 3-1. Tightening kelly bar (lower) packing Unit

3-3