CHAPTER 3

OPERATOR MAINTENANCE INSTRUCTIONS

Section I. BASIC ISSUE ITEMS LIST AND ITEMS TROOP INSTALLED OR AUTHORIZED

3-1. Basic Issue Items and Troop Installed Items

Basic issue items list and items troop installed or

authorized are not applicable.

Section II. LUBRICATION INSTRUCTIONS

lubrication clean of lubricants. Before lubricating the

3-2. Detailed Lubrication Information

equipment, wipe all lubrication points free of dirt and

a. General. Keep all lubricants in closed containers

grease. Clean all lubrication points after lubricating to

and store in a clean dry place away from external heat.

prevent accumulation of foreign matter.

Allow no dust or other foreign material to mix with the

lubricants. Keep all lubrication equipment clean and

3-3. Points of Lubrication

ready for use.

Service the lubrication points at proper intervals as

b. Cleaning. Keep all external parts not requiring

specified in Lubrication diagram this manual

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

deficiency is noted during operation which would

3-4. General

damage the equipment if operation were continued. All

To insure that the earth auger is ready for operation at

deficiencies and shortcomings will be recorded together

all times. it must be inspected systematically so that

with the corrective action taken on DA Form 2404,

defects may be discovered and corrected before they

Equipment Inspection and Maintenance Worksheet, at

result in serious damage or failure. The necessary

the earliest possible opportunity.

checks and services to be performed are listed as

described in paragraph 3-5. The item numbers indicate

3-5. Preventive Maintenance Checks and Services

the sequence of minimum inspection requirements.

Preventive maintenance checks and services to be

Defects discovered during operation of the unit will be

performed by the operator are listed in table 3-1.

noted for future correction to be made as soon as

operating has ceased. Stop operation immediately if a

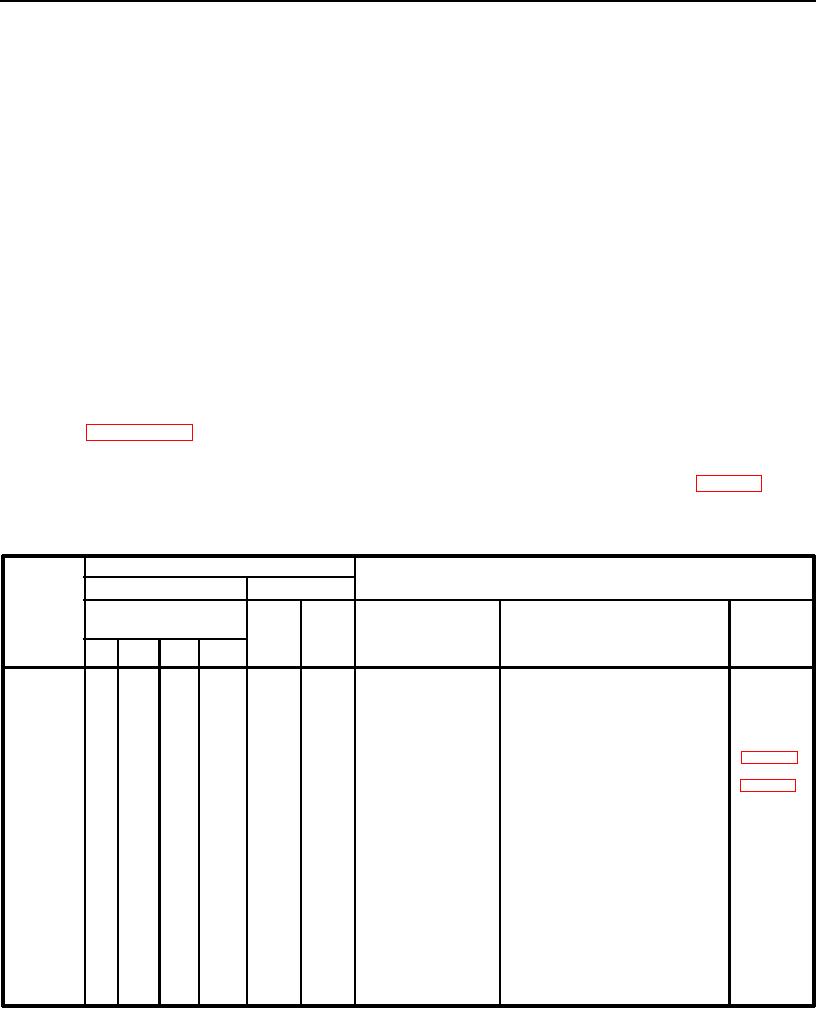

Table 3-1. Preventive Maintenance Checks and Services

Interval

B Before operation A After operation

M Monthly

Operator

Org

D During operaton

W Weekly

Q Quarterly

Item

Daily

Number

M

Q

Item to be inspected

Procedure

References

B

D

A

W

1

X

Muffler and pipes

Visually inspect for exhaust leakage due

(fig 4-24)

to corrosion, loose clamps, or damaged

gaskets Refer damage to organizational

maintenance.

2

X

Radiator

Check coolant level. Fill to 2 inches below

filler neck.

3

X

Fan belt

Inspect for frayed or damaged edges

(para 4-15a.)

Check for proper adjustment. Adjust-

ment should be 1/2 inch deflection

between pulleys Refer to organizational

maintenance.

3-1