TM 5-3805-296-23-1

0022

Table 1. 0100 Engine Oil Pressure Sensor Diagnostic Codes Continued.

022

CID FMI

TEST OR INSPECTION

CORRECTIVE ACTION

3. Disconnect connector CM-C1

0100-03 Engine Oil Pressure

(WP 0012, Figure 30) from engine

Sensor Voltage Above

ECM.

Normal Continued

4. Using digital multimeter

Resistance 5.0 Ohms or Less

(WP 0540), measure resistance

Replace engine ECM (WP 0252).

between connector CM-C1

Proceed to Test Step 7.

terminal 17 and terminal 28

Resistance Greater Than 5.0 Ohms

(WP 0012, Figure 30).

Replace basic engine wiring harness

(WP 0251).

Proceed to Test Step 7.

Test Step 7. Verify Malfunction is

Resolved.

1. Ensure all harness connectors are

connected.

2. At MSD, check for active

100-3 Engine Oil Pressure Sensor

Voltage Above Normal Becomes

diagnostic codes (WP 0008).

Inactive Proceed to step 3.

100-3 Engine Oil Pressure Sensor

Voltage Above Normal Remains

Active Repeat troubleshooting from

the beginning.

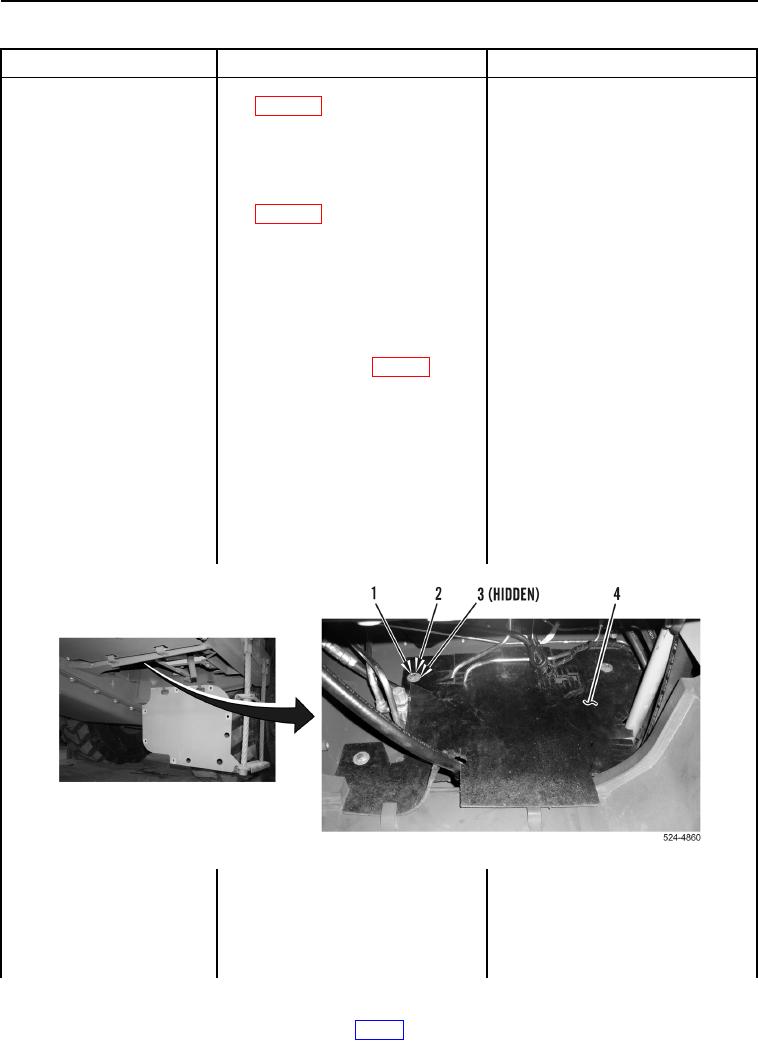

3. Install splash shield

(Figure 2, Item 4), four bushings

(Figure 2, Item 3), washers

(Figure 2, Item 2), and bolts

(Figure 2, Item 1) on machine.

Figure 2. Splash Shield and Retaining Hardware.

0022

4. Install left frame access plate

(WP 0376).

5. Troubleshooting complete.