TM 9-4940-568-34

7-10

7-3. CYLINDER BLOCK REPAIR AND DE-GLAZING INSTRUCTIONS (CONT).

c.

De-Glazing and Honing.

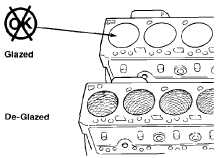

NOTE

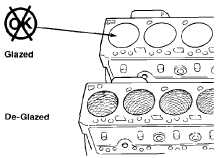

New piston rings may not seal in

glazed cylinder bores.

De-glazing gives cylinder bore

the correct surface finish required

to seat the rings.

(1)

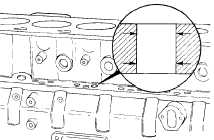

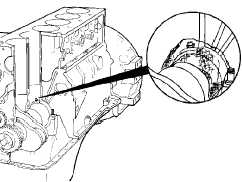

If necessary wrap connecting rod journals

with a clean cloth and cover cloth with

waterproof tape.

(2)

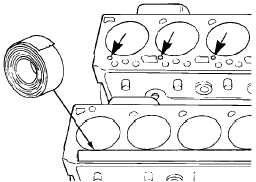

Place a clean shop towel around top main

bearing saddle to deflect water and residue

from piston cooling nozzles.

(3)

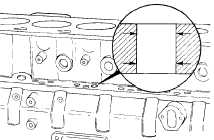

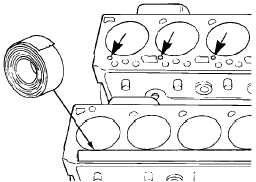

Also cover lubricating holes and tappet

holes in top of cylinder block with

waterproof tape.

(4)

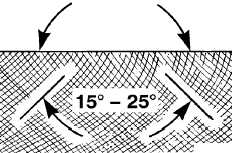

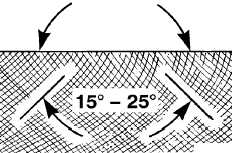

A correctly de-glazed surface will have a

crosshatched appearance with lines at

15-to-25 degree angles with top of cylinder

block.

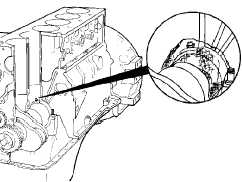

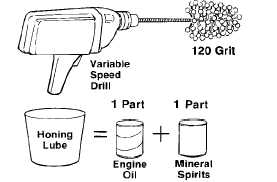

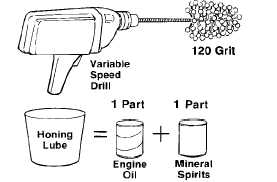

(5)

Using a drill, fine grit flex-hone and a

mixture of equal parts of mineral spirits and

engine lubricating oil, de-glaze the cylinder

bores.