A

B

TM 9-4940-568-34

7-9

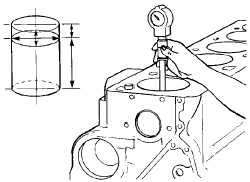

NOTE

Do not proceed with in-chassis

overhaul if cylinder bores are

worn beyond specifications.

Oversize pistons and rings are

available for re-bored cylinder

blocks.

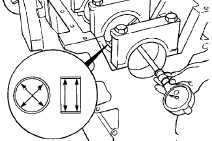

(9)

Check for out-of-roundness and taper of

bore. Tolerance for out-of-roundness is

0.0015 in. (0.038 mm) measured in 1.00 in

(25.4 mm) distance. Tolerance for taper is

0.003 in. (0.76 mm) measured in 4.50 in.

(144.3 mm) distance.

Bore I.D. Min. – 4.0157 in. (101.99 mm)

Bore I.D. Max – 4.0203 in. (102.116 mm)

Bore Out of Round Max. – .0015 in. (.035 mm)

Bore Taper Max. – .003 in. (.076 mm)

(10)

If tolerances exceed limits block must be

bored or replaced. Refer to de-glazing and

honing section.

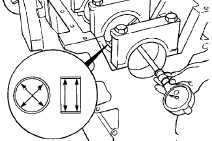

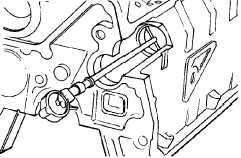

(11)

Inspect tappet bores for scoring or

excessive wear. Minimum diameter should

be 0.630 in. (16.00 mm) and maximum

diameter should be 0.632 in. (16.05 mm).

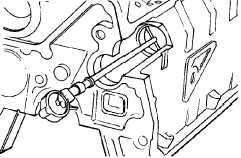

(12)

Measure the main bearing bore diameter.

The maximum diameter with bearing

installed is 3.272 in. (83.106 mm)

(Para 7-5).

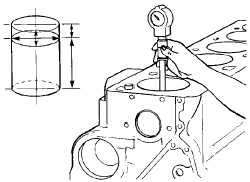

(13)

Measure the camshaft bore diameter. The

maximum measurements are listed below.

2.2543 in. (57.258 mm) (without bushing) No. 1 only

2.1317 in. (54.146 mm) No. 1 with bushing

2.1324 in. (54.164 mm) No. 2 through No. 7