TM 9-4940-568-20

3-62

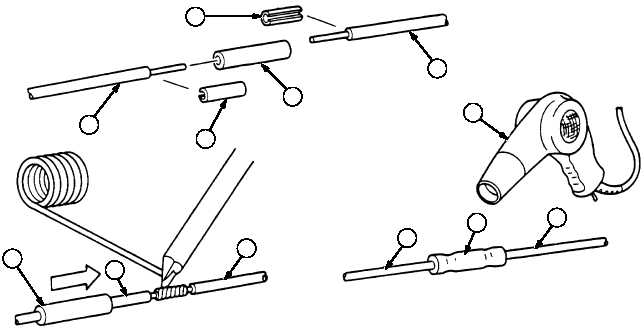

3-16. WIRING HARNESS MAINTENANCE (CONT).

c.

Wire Splicing Using Solder Method.

11

8

9

10

9

8

10

8

8

8

8

10

REPAIRING BROKEN WIRE

NOTE

This method makes a stronger and more permanent repair. Use this method whenever

possible.

If repairing a broken wire, perform Steps (1) thru (7) only. If a section of wire is being

replaced, perform Steps (8) thru (13).

(1)

If needed, remove broken wire (8).

(2)

Remove .75 in. (1.9 cm) of insulation (9) from both ends of wire (8).

(3)

Slide a three inch (7.62 cm) piece of proper size heat shrink tubing (10) over one end of wire (8).

(4)

Twist the bare ends of wire (8) together and solder. Make sure solder flows evenly onto both ends of

wire (8).

To prevent personal injury, allow solder joint to cool before handling.

To prevent personal injury, never use an open flame to apply heat shrink tubing.

Do not overheat the heat shrink tubing. It will split or melt and have to be replaced.

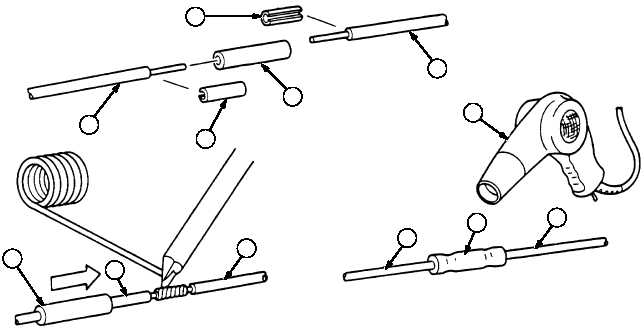

(5)

Slide heat shrink tubing (10) over solder joint.

(6)

Make sure solder joint is centered in heat shrink tubing (10).

(7)

Heat the heat shrink tubing (10) with a heat gun (11). Allow heat shrink tubing (10) to shrink until tight

on solder joint and insulation of wire (8).