TM 9-4940-568-20

3-61

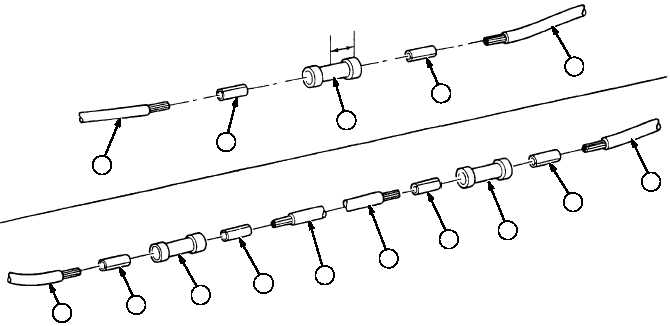

b.

Wire Splicing Using Butt Connectors.

4

5

6

7

4

5

6

6

5

5

4

4

5

5

7

REPAIRING BROKEN WIRE

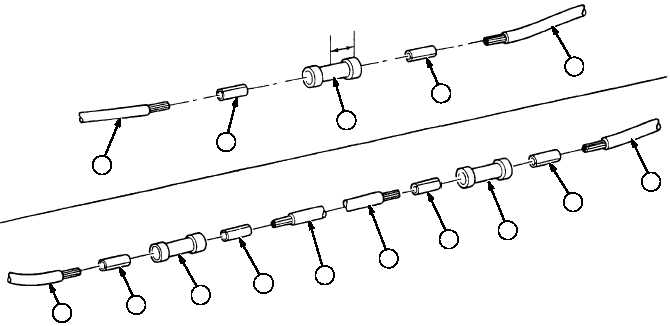

REPLACING SECTION OF DAMAGED WIRE

A

NOTE

Wherever possible, use solder method of wire splicing. Refer to section c of this

paragraph.

If reparing a broken wire perform steps (1) through (4) only. If section of wire is being

replaced, perform Steps (5) through (11).

(1)

Remove damaged piece of wire (4).

To prevent equipment damage, always use proper gage wire and proper size butt

connectors.

(2)

Remove insulation (5) from both ends of wire (4) equal to the length of dimension A.

(3)

Install butt connector (6) over bare ends of wire (4) and crimp firmly at both ends.

(4)

Inspect splice to make sure no bare wire (4) is visible.

(5)

If a section of wire (4) is being replaced, install two butt connectors (6), one onto each bare end of wire (4).

(6)

Crimp one end of both butt connectors (6) firmly in place over wire (4).

(7)

Measure the distance between the two open ends of the two butt connectors (6).

(8)

Cut a section of new wire (7) one inch (2.54 cm) longer than the distance measured in step (7).

(9)

Remove insulation (5) from both ends of new wire (7), equal to dimension A.

(10)

Install bare ends of new wire (7) into butt connectors (6) and crimp firmly into place.

(11)

Inspect splice and make sure that no bare wire (4 or 7) is visible.