TM 9-2330-389-14&P

Section II. INSTALLATION INSTRUCTIONS

5-2.

INSTALL TRACKED SUSPENSION.

This task covers:

a.

M200A1 Trailer Axle/Tire Assembly Removal

b.

M200A1 Trailer Modifications

c.

Tracked Suspension Installation

Initial Setup:

Equipment Condition:

Lubrication fitting (six required), MA125-21 025 (refer

Trailer parked on flat level surface.

to SC 4910-95-CL-A74)

MICLIC tiedown (two required) (Item 10, Appendix G)

Tools:

Rear fender (two required) (Item 5, Appendix G)

Common No. 1 tool set

Rear mounting bracket assembly (two required ) (Item

General mechanic's tool set

2, Appendix G)

Crane, wheel mounted, NSN 3810-01-165-0647

Right lower fender support (two required) (Item 9,

Master mechanic's tool kit

Appendix G)

Self-locking nut (four required), 419908PC40 (refer to

Materials/Parts:

TM 9-2330-205-14&P)

Center mounting bracket assembly (two required)

Self-locking nut (two required), MS21083N14 (refer to

(Item 3, Appendix G)

TM 9-2330-205-14&P)

Cotter pin (two required), MS24665-283 (refer to

Tiedown (four required) (Item 7, Appendix G)

TM 9-2330-205-14&P)

Track suspension, NSN 2330-01-360-3865

Fender template (Item 1, Appendix G)

Upper fender support (two required) (Item 6,

Forward mounting bracket assembly (two required)

(Appendix G)

(Item 4, Appendix G)

Left lower fender support (Item 8, Appendix G)

Personnel Required: Two

Lockwasher (eight required), MS35338-44 (refer to

TM 9-2330-205-14&P)

Lockwasher (eight required), MS35338-51 (refer to

TM 9-2330-205-14&P)

Use only on MOD zero (MOD 0) on MICLICs.

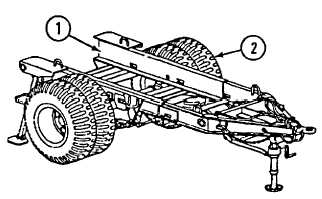

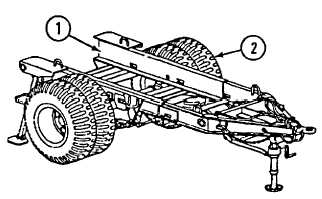

a.

M200A1 TRAILER AXLE/TIRE ASSEMBLY

REMOVAL.

1.

Raise trailer (1) with hydraulic jack until tires (2)

just clear ground. Support trailer (1) using jack

stand or blocking under rear comer. Remove

hydraulic jacks.

5-3