TM 9-2330-389-14&P

4-23.

SERVICE BRAKE MAINTENANCE (Con't).

NOTE

Perform steps 10 and 11 only if backing plate needs to be removed.

10.

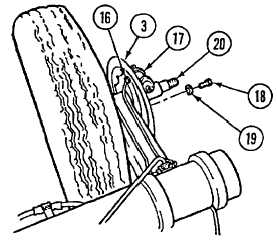

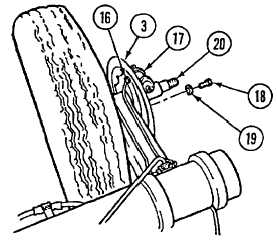

Position drain pan to catch brake fluid. Disconnect tube assembly (16) from hydraulic wheel cylinder (17).

11.

Remove five machine bolts (18),five flat washers (19), and backing plate (3) from front frame assembly spindle

(20).

b.

CLEANING AND INSPECTION

WARNING

·

Dry cleaning solvent P-D-680 is toxic and flammable. Always wear protective

goggles and gloves, and use only in a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat. The solvent's flash point is 100° F-138° F (38° C-59° C).

If you become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts eyes, immediately wash your eyes and get

medical aid.

·

DO NOT handle brakeshoes, brakedrums, or other brake components unless

area has been properly cleaned. There may be asbestos dust on these

components, which can be dangerous if you touch it or breathe it. Wear an

approved filter mask and gloves. Never use compressed air or a dry brush to

clean brake components. Dust may be removed using an industrial-type

vacuum cleaner. Clean dust or mud away from brake components with water

and a wet, soft brush or cloth. Failure to follow this warning may result in

serious illness or death to personnel.

1.

Clean all parts with dry cleaning solvent.

2.

Inspect all parts for damage. Replace any damaged parts.

3.

Inspect brakeshoe surfaces for cracks, distortion, and excessive wear. Brakeshoe linings should have a minimum

thickness of 1/8 in. (3.2 mm). Replace brakeshoes if cracked or if lining thickness is less than 1/8 in. (3.2 mm).

4-23