6

TM 5-3805-296-10

OPERATOR MAINTENANCE

-

THEORY OF OPERATION

0

003

INTRODUCTION

0003

1. The Military 621G Scraper consists of the following functional systems: engine, powertrain, brake systems,

electrical, and implement hydraulic systems.

2. This work package explains how the systems and components of the machine work together. A functional

description is provided for each major component and system.

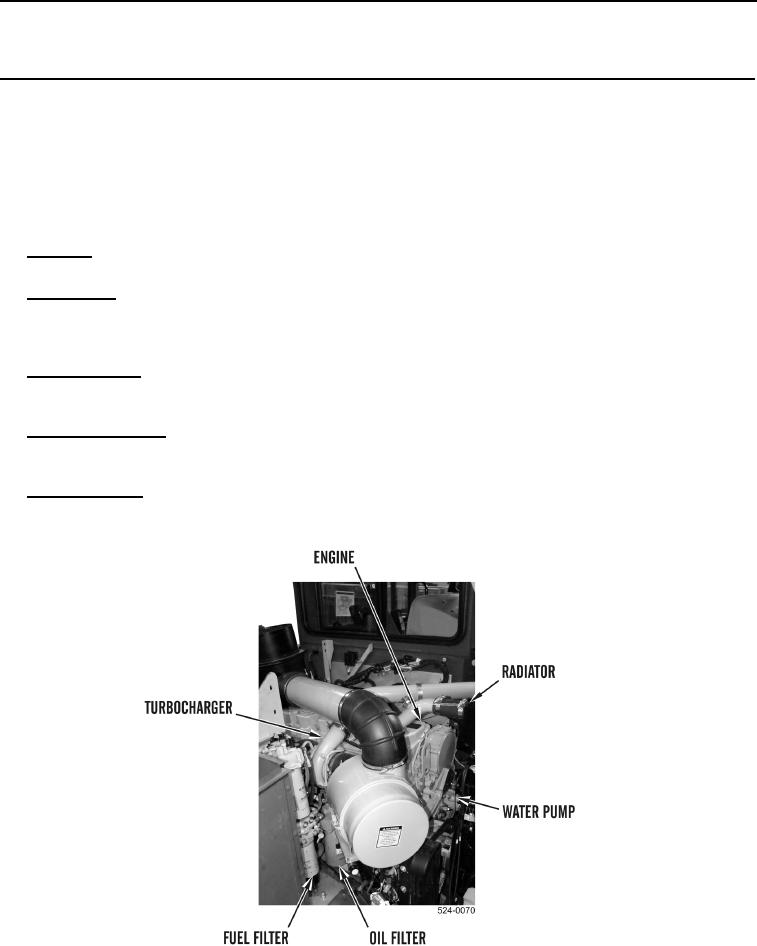

ENGINE

0003

1. General. The tractor is equipped with a Caterpillar C15 Acert turbocharged diesel engine with six in-line cylin-

ders, generating 365 horsepower @ 1,800 rpm.

2. Fuel System. The engine is powered with a direct fuel injection system. Fuel from the fuel tank is pulled

through two secondary fuel filters by a fuel transfer pump that is an integral part of the engine governor. Drilled

passages in the cylinder head provide a continuous flow of fuel to the injectors. Unused fuel is returned to the

fuel tank.

3. Cooling System. The cooling system consists of a belt-driven circulating water pump, 197F (92C) thermo-

stat for controlling coolant flow, engine-driven fan, oil cooler, and radiator. The cooling system cools the engine

by circulating pressurized ethylene glycol-based coolant through the engine and radiator.

4. Lubrication System. The engine lubrication system consists of a gear-driven oil pump, oil filter, oil cooler, and

oil pan. The engine is lubricated by cooled and pressurized oil which is circulated through the engine block and

head.

5. Exhaust System. The exhaust system removes exhaust gases from the engine through the exhaust manifold

Figure 1. C15 Acert Diesel Engine.

0003