4

3

1

2

5

TM 9-4940-568-10

3-35

Table 3-1. Troubleshooting - CONT.

Malfunction

Test or Inspection

Corrective Action

CRANE (CONT)

6.

HOIST DOES NOT SPOOL CABLE PROPERLY.

Wire rope can become frayed or contain broken wires. Wear heavy leather-palmed work

gloves when handling wire rope. Frayed or broken wires can injure hands.

Never let moving wire rope slide through hands, even when wearing gloves. A broken wire

could cut through glove and cut hand.

Step 1. Lower load to the ground as soon as a mis-spooled condition is observed.

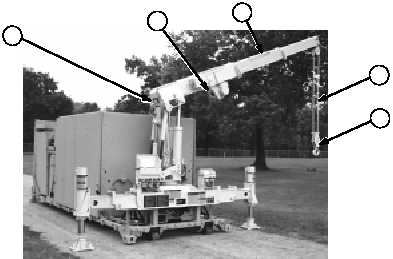

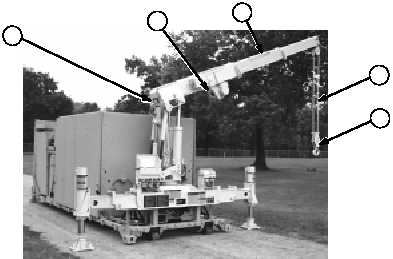

Step 2. Raise the boom (1) to the maximum angle, telescope out to maximum length, and lower the

hook (2) to just above ground level. At this point there should be approximately five wraps

of cable remaining on the drum (3).

Step 3. Inspect the entire length of hoist cable (4) and note any obvious kinks. If kinks are noted,

position the crane (5) as necessary to inspect the hoist cable for damaged wires. Refer to

hoist cable criteria in PMCS Table (Para 2-11).

If cable is still serviceable, return the crane to the position described in Step 2.

If cable is unserviceable, notify Unit Maintenance.