TM 9-2330-359-14&P

5-11. SPRINGS AND EQUALIZING BEAMS REPLACEMENT (Con’t).

b. CLEANING AND INSPECTION

1.

2.

3.

4.

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F (38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh air and medical help. If solvent contacts

eyes, immediately wash your eyes and get medical aid.

Clean springs and equalizing beam with dry

cleaning solvent.

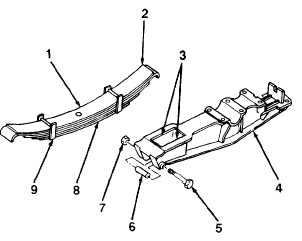

Inspect leaves (8) and clips (9) for cracks and

breaks. Inspect lower leaf of main spring at

contact of spring bearing seat for excessive wear.

Replace spring if damaged.

Inspect equalizing beam for structural cracks or

damage. Inspect spring hangers (2) for cracks.

Replace defective components.

Inspect thickness of equalizing beam walls (3).

Equalizing beam wall measurement should read

43/8 in. (1 1.11 cm). If wear exceeds 1/4 in. (6.35 mm),

replace equalizing beam.

c.

INSTALLATION

Springs are

spacer.

NOTE

installed the same way on all models except M872A3 does not have pipe

1.

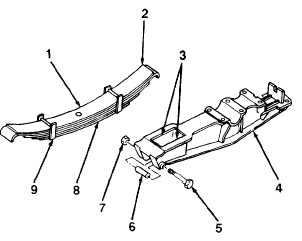

Position equalizing beam (4) and springs (1) on semitrailer.

2.

Install pipe spacer (6) on springs (1) and equalizing beam (4) with screw (5) and new locknut (7).

FOLLOW-ON TASKS:

l Install trunnion bushing (para 4-45).

l Install axles (para 4-30).

TA508089

5-18