2-03

Ignition System

2-03

4.

While holding the high tension lead approximately 3/16 inch from

the cylinder head or any other good ground, crank the engine

with an auxiliary starter switch.

If the spark Is good, the trouble lies in the secondary circuit.

If there is no spark or a weak spark, the trouble is in the primary

circuit. coil to distributor high tension lead, or the coil.

Primary Circuit

A breakdown or energy loss in the primary circuit can be caused

by: defective primary wiring. or loose or corroded terminals; burned,

shorted, sticking or improperly adjusted breaker points; a defective

coil; or defective condenser.

A complete test of the primary circuit consists of checking the

circuit from the battery to the coil, the circuit from the coil to ground,

and the starting ignition circuit.

Excessive voltage drop in the primary circuit will reduce the

secondary output of the ignition coil, resulting in hard starting and poor

performance.

To isolate a trouble in the primary circuit, use a voltmeter and

perform the following tests: Battery to Coil, Starting Ignition Circuit,

Resistance Wire, Coil to Ground, or Breaker Points.

Secondary Circuit

A breakdown or energy loss in the secondary circuit can be

caused by: fouled or improperly adjusted spark plugs; defective high

tension wiring; or high tension leakage across the coil, distributor cap

or rotor resulting from an accumulation of dirt.

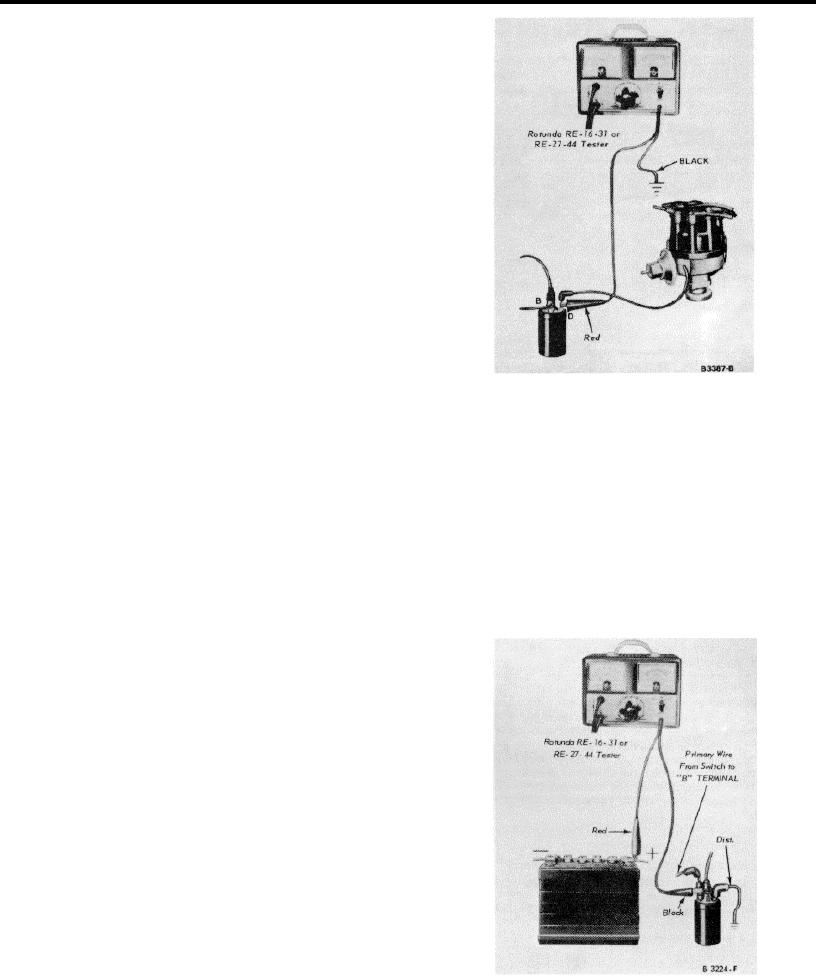

FIG. 4. Battery-to-Coil and Starting Ignition Circuit Test

To check the spark intensity at the spark plugs, thereby isolating

an ignition problem to a particular cylinder, proceed as follows:

Starting Ignition Circuit Voltmeter Test

1.

Disconnect a spark plug wire. Check the spark intensity of

I.

Connect the voltmeter leads as shown in Figure 4.

one wire at a time.

2.

Disconnect and ground the coil to distributor high tension lead at

2.

Install a terminal adapter in the terminal of the wire to be

the distributor.

checked. Using insulated pliers, hold the adapter approximately

3.

With the ignition ,witch off, crank the engine with an auxiliary

3/16 inch from the exhaust manifold and crank the engine, using

starter switch while observing the voltage drop.

a remote starter switch. The spark should jump the gap

4.

If the voltage drop is 0.4 volt or less, the starting ignition circuit is

regularly.

satisfactory.

3

If the spark intensity of all the wires is satisfactory, the coil,

5.

If the voltage drop is greater than 0.4 volt, clean and tighten the

condenser, rotor, distributor cap and the secondary wires are

terminals in the circuit or replace the wiring as necessary.

probably satisfactory.

If the spark is good at only some wires, check the resistance of

Coil to Ground Voltmeter Test - (Conventional - System)

the faulty leads.

1.

Connect the voltmeter leads as shown in Figure 5.

If the spark is equal at all wires, but weak or intermittent, check the

2.

Close the breaker points.

coil, distributor cap and the coil to distributor high tension wire. The

3. Turn all accessories off.

wire should be clean and bright on the conducting ends, and on the

coil tower and distributor sockets. The wire should fit snugly and be

bottomed in the sockets.

IGNITION SYSTEM TESTS

Battery to Coil Voltmeter Test

1.

Connect the voltmeter leads as shown in Figure 4.

2.

Connect a jumper wire from the distributor terminal of the coil to

a good ground on the distributor housing.

3.

Turn the accessories off.

4.

Turn the ignition switch on.

5.

If the voltmeter reading is between 4.5 and 6.9 volts, the

primary circuit from the battery to the coil is satisfactory.

6.

If the voltmeter reading is greater than 6.9 volts, check

the following:

The battery and cables for loose connections or corrosion

The primary wiring for worn insulation, broken strands, and

loose or corroded terminals

If the voltmeter reading is less than 4.5 volts the ignition

resistor should be replaced.

Check the starter-relay-to-ignition switch for damage.

FIG. 5. Coil to Ground Test