TM 5-3815-224-14&P

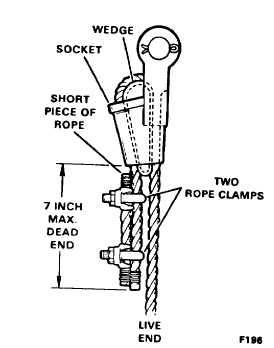

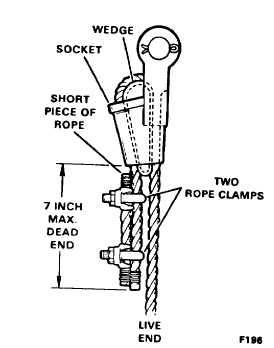

Figure 5. Installing a Rope Socket

WARNING

Wear approved leather gloves when working

with wire rope.

1.

Thread the rope through the socket and bring it

around in an easy to handle loop. Allow the rope to

assume its natural lay; do not twist the rope.

WARNING

The live end of the rope must be in a straight line

through the socket.

2.

The dead end of the rope must not extend more

than 7 inches past the end of the socket. Insert the

wedge in the rope loop and pull the wedge and rope loop

tight enough to hold the wedge in position during

handling. Final wedge positioning will take place under

full operating loads.

WARNING

Make sure the live end of the rope is not kinked

at the point where it leaves the socket.

3.

After the socket is pinned to the boom point or

hook block, apply gradually increasing loads until the

wedge is seated in the socket. Avoid any sudden shock

loads before the wedge is in its final position. When

seated properly, the wedge will just protrude beyond the

end of the socket.

4.

Cut a piece of rope and secure it to the dead end

of the rope with two clamps as shown in Figure 5.

DISMANTLING

UNREEVING

WARNING

Keep hands and clothing clear of rotating drums.

Carefully lower the boom and jib to a horizontal position

and install suitable cribbing under each section of the

boom and jib. Lower the boom and jib onto the cribbing.

Disconnect the hoist lines at the dead end and unreeve

the hook block(s) and boom point. Slowly wind the rope

onto the drum by moving the appropriate drum lever to

the raise position. A lead or brass hammer may be

useful in tapping the rope over as it is being wound on

the drum. Do not use a steel hammer or pinch bar.

These can readily cause damage to the rope. After the

boom and jib hoist lines have been unreeved from the

boom point, wind the hoist lines onto their respective

drum.

NOTE

A tension should be induced into the rope by

providing some means of braking the wire rope.

A tight winding is imperative.

CRANE BOOM. To remove the crane boom and jib,

proceed as follows:

WARNING

Do not stand under the boom or inside the boom

structure when removing pins. The boom could

fall if improperly supported and could cause

serious injury.

CAUTION

If machine is equipped with a fairlead, swing it

out of the way to fully lower the boom. See

FAIRLEAD and LAGGING Manual (TM 5-3815-223

-1 4&P).

1.

Support the jib with suitable cribbing (see Figure

3): Remove the jib suspension cables and jib strut.

2.

Remove the pins which secure the jib to the

boom, and remove the jib.

3.

Disconnect

any

electrical

cables

that

are

attached to the boom. Coil the cables and securely

fasten them to the machine cab.

4.

Relax the boom suspension and connect the guy

lines at the first insert adjacent to the tip section.

Remove the extra guy lines from the boom point.

5.

Engage the boom hoist and lift the boom just

enough to remove the bottom connecting pins from the

tip and insert.

6