TM 5-3815-224-14&P

1.

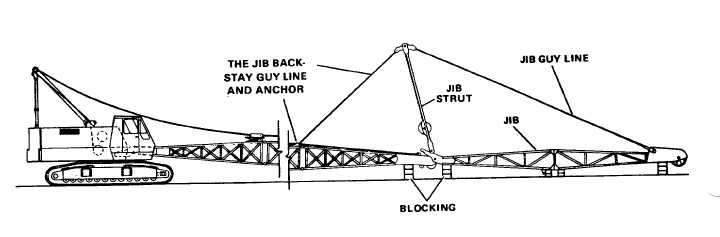

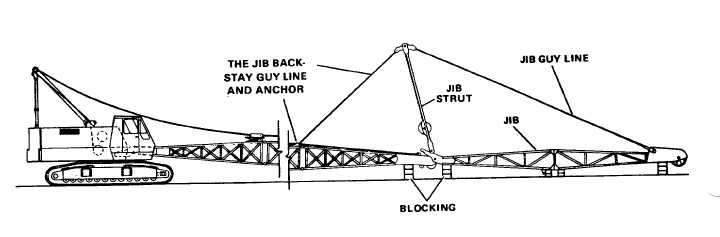

Raise the boom and move the machine up to the

cribbed up jib. Secure the jib to the boom point. See

Figure 3.

2.

Install the jib guy lines from the jib point to the

strut and from the strut to the jib backstay anchor. See

Figure 3 for information on the jib backstay anchor. The

jib suspension line should be adjusted so that the offset

angle of the jib to the boom, under load, does not exceed

the limitations shown on the rating plate. The maximum

jib offset angle is 300 as shown in Figure 1.

ERECTING THE CRANE BOOM. To erect the crane

attachment, proceed as follows:

NOTE

Consult the load rating chart for maximum boom

(or boom plus jib) that can be erected and

required conditions during erection.

1.

Check all reeving and inspect the complete

crane to be sure that everything is in order before

attempting

to

hoist

the

attachment.

Inspect

all

connections to be sure pins are locked. Since the boom

hoist lines are very heavily loaded while erecting a crane

boom, they must be in good condition.

2.

The boom must be raised from a horizontal

position. Support the boom in this position with the

blocking used during assembly.

3.

Erect the crane boom, being careful to take up

slack in the load lines as the boom goes up to prevent

any possibility of fouling lines.

LOWERING THE CRANE BOOM. To lower the crane

attachment, move the boom hoist lever forward and

slowly lower the boom onto blocking.

CAUTION

If machine is equipped with a fairlead, swing it

out of the way to fully lower the boom. See

FAIRLEAD and LAGGING Manual. (TM 5-3815-

223-14&P).

The load hoist lines must have adequate slack

when lowering the crane attachment to prevent

any possibility of these lines becoming taut.

These lines will tend to tighten as the attachment

is lowered, and if adequate slack is not allowed,

the attachment cannot be lowered completely.

Damage to the attachment may also result.

REEVING

JIB LOAD LINE REEVING. The reeving on the jib hoist

line depends on the load to be lifted and the speed at

which the load is to be lifted or lowered. Consult the

rating plate for a particular load. Typical reeving

diagrams recommended for the jib line is shown in Table

1. The drum is over-spooled when using the jib line. On

the 5060 crane the left drum is the jib load line. Table 1

gives rope size and length information.

INSTALLING ROPE ON DRUMS. The manner in which

a new or replacement wire rope is installed on the drums

will, to a large measure, determine the service life of that

rope. Improperly wound ropes will cause undue crushing

of the rope, doglegs, kinks, excessive abrasion and

cutting of the individual wires. Bad spooling also causes

uneven application of force and motion. This results in

fast fatiguing of the rope from the hook block, or

spreader, to the drum.

Figure 3. Attaching Jib

4