TM 5-3815-224-14&P

CAUTION

The following five precautionary steps should be

taken, particularly with a replacement wire rope,

before starting the actual installation of the rope.

1.

A check should be made of the drum to

determine the condition, size and shape of the drum

grooves, if so equipped.

2.

Drum flanges should be checked to determine

the extent, if any, of undercutting at the base of the

flange.

3.

Dirt, grit or any other type of debris should be

cleaned off the drum.

4.

Bearings should be checked.

5.

Cracks or breaks in the drum should be

reported.

Whenever any of these conditions are observed, the

drum should be removed from service and properly

cleaned, repaired or replaced. This recommendation is

made not only to improve or maintain good rope life, but

to eliminate a potential hazard.

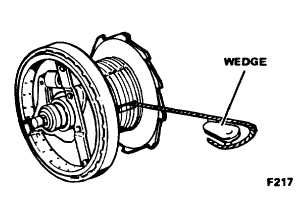

After establishing the satisfactory condition of the drum,

mount the reel of wire rope on suitable jacks. Reeve the

boom hoist or load line and attach the rope to the drum

as shown in Figure 4.

NOTE

A tension should be induced into the rope by

providing some means of braking the shipping

reel while installing the rope on the drum. A tight

winding is imperative.

Figure 4. Securing Rope to Drum

WARNING

Keep hands and clothing clear of the rotating

drum.

Establish a means of communicating with the operator

and have him slowly wind the rope on to the drum by

moving the appropriate drum lever to the raise position.

A lead or brass hammer may be useful in tapping the

rope over as it is being wound on the drum. Do not use

a steel hammer or pinch bar. These can readily cause

damage to the rope.

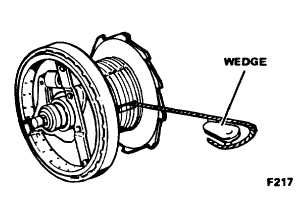

USE OF WEDGES. The dead end of the rope is

attached with a wedge type rope socket. The rope

socket should be installed on the boom as follows (see

Figure 5):

5