TM 9-6230-210-13&P

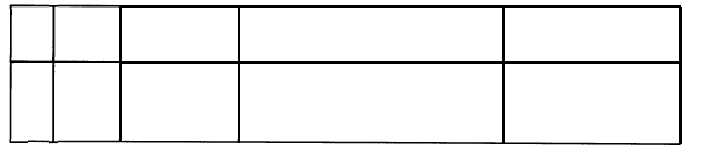

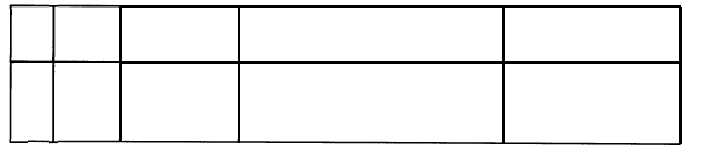

Table 4-2. Unit Preventive Maintenance Checks and Services - continued

Location

Item

N o .

Interval

of Item to

Check/Service

Prodedures

Not Mission

Capable If:

7

Quarterly

Splash Panel

Inspect for loose or missing hardware and

cracked or broken welds..

Generator Mount-

lnspect for loose, missing, or stripped

ing Hadwere

threads on mounting hardware.

8

Quarterly

4.11

a.

SECTION IV. UNIT TROUBLESHOOTING

GENERAL

PROCEDURES

This table lists common malfunctions that you may find with your equipment. Perform the inspections and

corrective actions in the order they appear in the table.

b. This table cannot list all the malfunctions that may occur, all the inspections needed to find the fault, or all of the

corrective actions needed to correct the fault. If the equipment malfunction is not listed or actions not listed to correct

the fault, notify your supervisor.

c. Refer to TM 9-2805-258-14 to troubleshoot your gasoline engine.

d. Refer to TM 9-6115-271-14 to troubleshoot your generator set.

e. Refer to TM 9-2330-251-14 to troubleshoot your trailer.

f. Table 4-3, Unit Troubleshooting Table is presented as flow diagrams for each malfunction listed. Each diagram

provides the troubleshooting procedures and corrective actions required to return the Floodlight Set to mission capable

readiness.

4-18