TM 9-4940-568-34

5-62

5-11. FLYWHEEL RING/GEAR AND FLYWHEEL HOUSING REPLACEMENT (CONT).

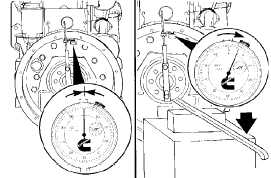

(6)

Rotate crankshaft until dial indicator is at 12

o’clock position and zero the gauge.

Do not force the crankshaft

beyond the point where bearing

clearance has been removed. Do

not pry against the flywheel

housing. These actions could

cause cause bearing clearance

readings.

(7)

Using a pry bar, raise rear of crankshaft to

its upper limit. Record the value as (d) in

the concentricity work sheet. This is the

vertical bearing clearance adjustment and

will always be positive.

(8)

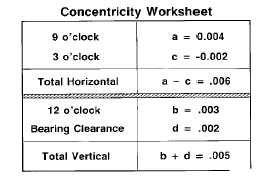

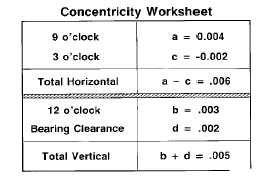

Using the concentricity work sheet,

determine the values for the “total vertical”

and “total horizontal” values.

(9)

The “total horizontal” is equal to the 9

o’clock reading, (a), minus the 3 o’clock

reading, (c).

(10)

The “total vertical” is equal to the 12

o’clock reading, (b), plus the bearing

clearance, (d).

Example:

6 o’clock = ref = 0

9 o’clock = ref = 0.004”

12 o’clock = ref = 0.003”

3 o’clock = ref = –0.002

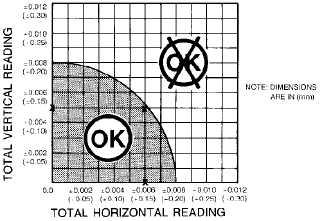

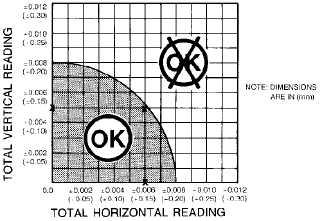

(11)

Using the work sheet and the numbers from

the example:

“total horizontal” value = 0.006”

“total vertical” value = 0.005”.