TM 9-2330-359-14&P

Assembly and Installation

GENERAL WELDING NOTES

Welding to be done in accordance with MIL-

STD-1261, CLASS 2. All fillet welds to be 1/8-inch

minimum.

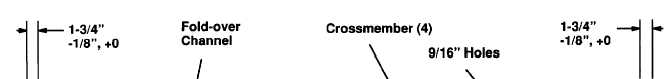

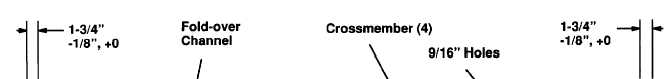

1. Space and position four crossmembers as shown with concave or sunken sides facing fold-over channel. Make

sure both outboard crossmembers have drilled holes and hole ends are positioned by channel cut-outs. Weld each

crossmember to channel, using four skip welds on each side and full welds on each end. Skip welds are approximately

1-1/2 inch long with 2- inch spacing between welds.

WARNING

Bulkhead extension weighs 80 to 90 Ibs. To avoid

injury, use two people to lift and position the exten-

sion.

2. Lift and position fold-over channel on bulkhead.

NOTE

Make sure fold-over channel is on the straight verti-

cal before welding hinge fold-overs. Otherwise,

hinge will misalign and channel will not fold down.

5-26 Change 1