TM 9-2330-238-14

Section VI. SUSPENSION

MAINTENANCE

5-16. TANDEM

SUSPENSION

BRACKET REPLACEMENT

This Task Covers:

a.

Removal

b.

Installation

Initial Setup:

Materials/Parts:

Tools/Test Equipment:

• Ten rivets

l General mechanic’s

tool kit

l Twelve Iockwashers

• Field automotive

supplemental

no. 1 shop set

References:

Personnel

Required:

Two

l TB 9-2300-247-40

1.

2.

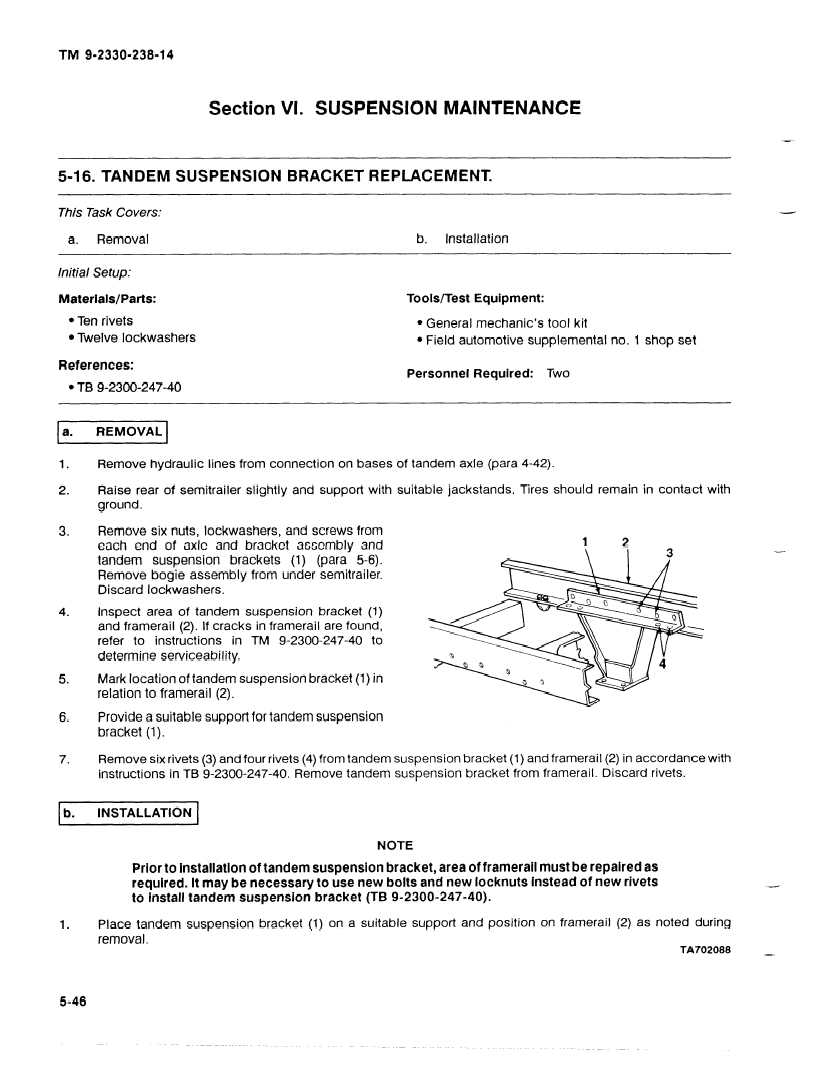

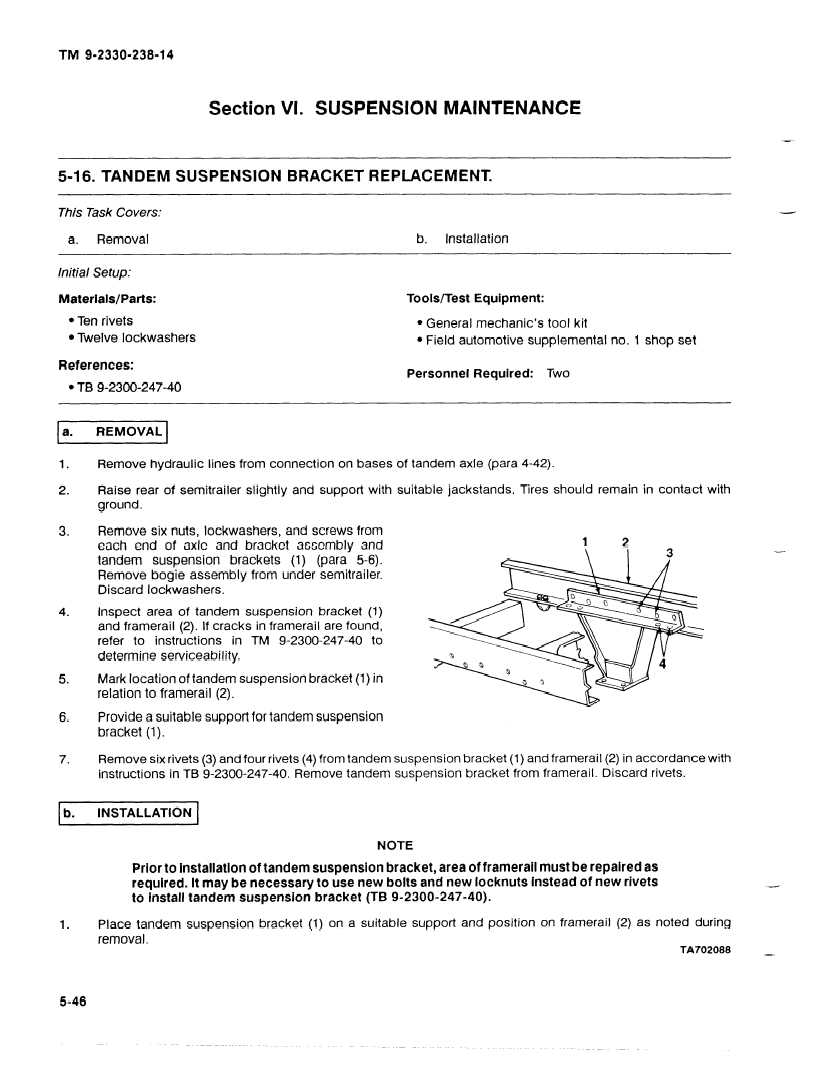

3.

4.

5.

6.

7.

Remove hydraulic

lines from connection

on bases of tandem axle (para 4-42).

Raise rear of semitrailer

slightly

and support

with suitable

jackstands.

Tires should

ground.

Remove

six nuts, Iockwashers,

and screws from

each

end

of axle

and

bracket

assembly

and

tandem

suspension

brackets

(1)

(para

5-6).

Remove

bogie

assembly

from under semitrailer.

Discard

Iockwashers.

Inspect

area of tandem

suspension

bracket

(1)

and framerail

(2). If cracks in framerail

are found,

refer

to

instructions

in

TM

9-2300-247-40

to

determine

serviceability.

Mark location of tandem suspension

bracket (1) in

relation to framerail

(2).

Provide a suitable support for tandem suspension

bracket

(1).

Remove six rivets (3) and four rivets (4) from tandem

remain in contact

with

suspension

bracket (1) and framerail (2) in accordance

instructions

in TB 9-2300-247-40.

Remove tandem

suspension

bracket from framerail.

Discard rivets.

with

NOTE

Prior to installation of tandem suspension bracket, area of framerail must be repaired as

required. It maybe

necessary to use new bolts and new locknuts instead of new rivets

to install tandem suspension

bracket

(TB 9-2300-247-40).

1.

Place tandem

suspension

bracket

(1) on a suitable

support

and position

on framerail

(2) as noted during

removal.

TA702088

5-46