TM 9-2330-238-14

5-5. AXLE MAINTENANCE (Con’t).

3.

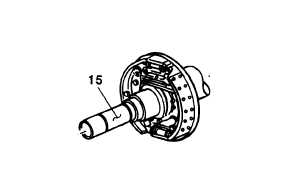

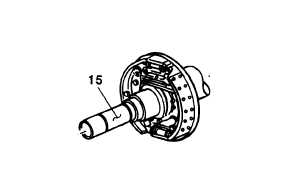

Inspect bearing seating surfaces (15) for wear.

Minimum diameter of 2.6245 inches (6.404 cm)

allowed.

4.

Inspect threads of axle spindles for wear, crossed

threads, or damage. Remove burrs with fine file or

hand chase threads if necessary.

d.

ASSEMBLY

1.

Install brakeshoe assemblies (para 4-38).

2.

Install eight bolts (3) in two spring guide bracket assemblies (2). Position spring guide brackets in place on axle

(7). Turn bolts until they hang freely without binding against axle.

3.

Position lower torque rod brackets (6) under axle (7) and aline holes with bolts (3). Install new Iockwashers (4)

and nuts (5) on each bolt.

4.

Position upper torque rod brackets (13) on axle (7). Install eight bolts (3) in upper torque rod bracket and turn

bolts until they hang freely without binding against axle.

5.

Position bracket plate (10) under axle (7) with eight bolts (3) in mounting holes. Install eight new Iockwashers (4)

and nuts (5) on bolts.

6.

Install hydraulic lines to each wheel cylinder with two fluid passage and ring spacers bolts (para 4-39).

7.

Install hydraulic line connector (11) to band on axle (7) with nut (9), new Iockwasher (8), and capscrew (12).

e.

INSTALLATION

1.

Position axle (7) on jack and move in place under semitrailer. Aline spring guide bracket assemblies (2) with

springs (1).

2.

Connect torque rods (14) to correct torque rod brackets on axle (para 4-57).

3.

Connect hydraulic hose to tee at center of axle (para 4-42)

TA702061

5-8