TM 5-3825-230-14&P

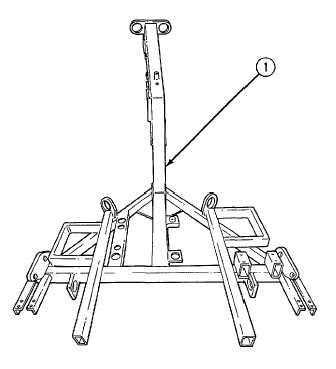

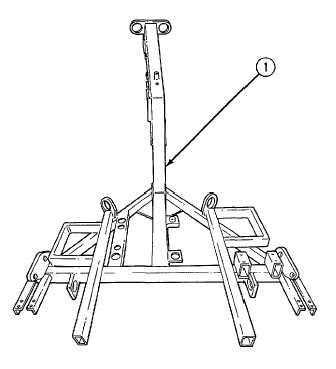

5-37. MAIN FRAME REPAIR.

This task covers:

a. Repair

b. Cleaning/Inspection

INITIAL SETUP

Tools

Equipment Condition

Tool Kit, Master Mechanic's

TM or Para

Condition Description

Para 4-77

24V wire harness

Shop Equipment, Machine Shop; Field

removed.

Maintenance, Basic, Less Power

Para 4-78

Broom hood wire harness

removed.

Equipment Condition

Para 4-75

Battery box removed.

TM or Para

Condition Description

Para 4-122

Saddle removed.

Para 4-24

Engine removed.

Para 4-87

Modified spindle

Para 4-94

Swing frame removed.

removed.

Para 4-123

Sprinkler lines

Para 4-40

Fuel tank removed.

removed.

Para 4-106

Hydraulic reservoir

Para 4-105

Hydraulic hoses removed.

drained.

Para 4-76

12V wire harness

removed.

a. Repair.

(1)

Welding and brazing may be used to repair

cracks in external steel parts, such as brackets,

panels, and light framework. Do not weld or

braze parts under great stress.

(2)

Bent or dented frame parts may be repaired by

straightening.

(3)

Painting. Instructions for preparation of material

for painting, how to paint, and material to be

used are in TM 43-0139. Stenciling and working

markings for military vehicles are called out in

TB

43-0209.

Data

plates

location

and

description are referenced in Chapter 2.

b.

Cleaning/inspection. Inspect mainframe for

cracks, dents, corrosion and warpage.

5-92