TM 5-3825-230-14&P

4-90. TIRE REPLACEMENT.

This task covers:

a.

Removal

b.

Cleaning/Inspection

c.

Installation

INITIAL SETUP

Tools

Equipment Condition

Shop Equipment, Automotive Maintenance and

TM or Para

Condition Description

Repair; Organizational Maintenance, Common

Para 4-88

Wheel removed.

No. 1, Less Power

General Safety Instructions

Materials/Parts

Always inflate tire in a safety cage.

Lubricant, tire bead, item 23 Appendix E

a.

Removal.

(1)

Slowly remove valve core (1), and allow all

air to escape.

(2)

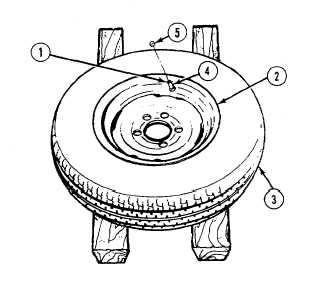

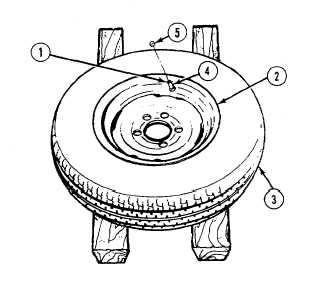

Place rim (2), and tire assembly (3) on

wooden blocks.

(3)

Attach pneumatic tire bead breaker to sides

of tire (3), and break tire bead away from

rim (2).

(4)

Insert curved end of two tire irons between

rim and tire bead about 5 in. (12 cm) apart.

(5)

Force both tools down and out to lift bead

over wheel rim.

(6)

Leave one tool in place and put second 5 in. (12 cm) away from first position. Repeat steps (5) and (6) until

side of tire is removed from rim.

(7)

Turn tire over and repeat steps (3) thru (6) driving other edge of tire over same side of rim as the first.

(8)

Remove valve stem (4) from rim (2).

b.

Cleaning/lnspection.

(1)

Use wire brush to remove all dirt and corrosion from rim.

(2)

Inspect rim (2) for cracks, deep pitting or dents.

(3)

Replace rim (2) if any significant damage is found (e.g. cracked weld, bent rim.)

4-157