3-05

Fuel System

3-05

expel one pint. Close the restrictor One pint or more of fuel

Capacity (Volume) Test

should be expelled within the specified time limit

With the fuel pump pressure within specifications. Test the

If the pump volume is below specifications, repeat the test using

capacity (volume) as follows:

an auxiliary fuel supply and a new fuel filter. If the pump volume

I.

Operate the engine at the specified idle rpm.

meets specifications while using the auxiliary fuel supply. Check for a

2.

Open the hose restrictor and expel the fuel into the container

restriction in the fuel supply from the tank and for the tank not venting

(Figure 3), while observing the time required to

properly

REMOVAL AND INSTALLATION

FUEL PUMP ASSEMBLY

Removal

2.

Position the new gasket on the pump in position against the

1.

Disconnect the inlet and outlet lines at the fuel pump.

mounting pad Make sure the rocker arm is riding on the

2.

Remove the pump attaching screws, then remove the pump and

camshaft eccentric (Turn the engine over until the fuel pump

the gasket Discard the gasket.

eccentric is on the low side of the stroke.)

3.

Press the pump tight against the pad. install the attaching

screws and alternately torque them to specifications

Installation

4.

Connect the fuel inlet and outlet lines.

1.

Remove all the gasket material from the mounting pad and

5.

()perate the engine and check for leaks

pump flange. Apply oil-resistant sealer to both sides of a new

gasket and to the threads on the attaching bolts.

HOLLEY 1940 ONE-BARREL

CARBURETOR

DESCRIPTION AND OPERATION

The Holley 1940 one-barrel carburetor used on the 300 CID

engines includes four basic fuel metering systems. The idle system

provides a reasonable rich mixture for smooth idle and a transfer

system that operates during low speeds The main metering system

provides the most economical mixture for normal cruising conditions

The accelerator pump system mechanically provides additional fuel

during acceleration. The power enrichment s stem provides a richer

mixture when high power output is desired In addition to these four

basic systems, there is a fuel inlet system that constantly supplies the

fuel to the metering system.

The choke system supplies a rich mixture to start the engine

when cold and a slightly richer than normal mixture for cold engine

operation The 1940 carburetor is equipped with a hand choke located

on the dash.

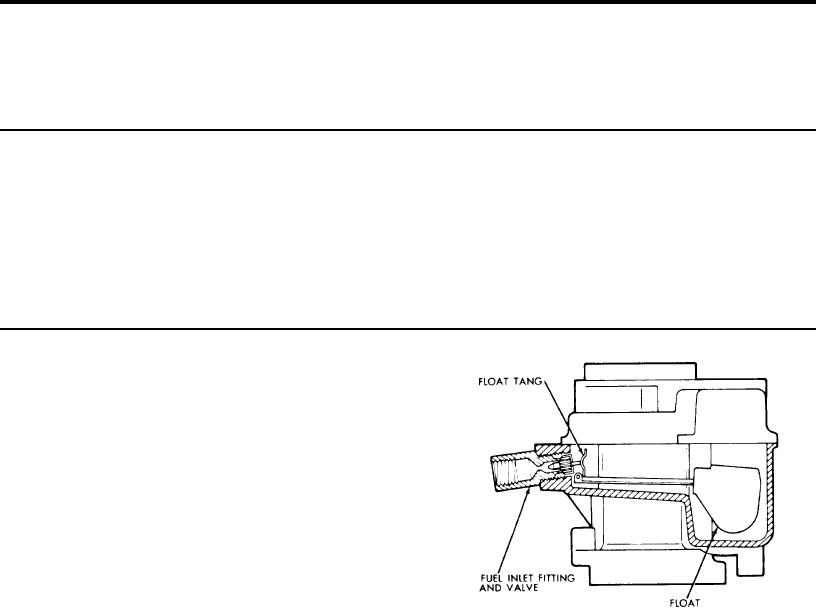

FIG. 4. Fuel Inlet System, Model 1940

FUEL INLET SYSTEM (FIG. 4)

All fuel enters the fuel bowl through the fuel inlet fitting in the

IDLE SYSTEM (FIG. 5)

carburetor body. The 'viton" tipped fuel inlet needle seats directly in

Fuel used during curb and low speed operation flows through

the fuel inlet fitting. The needle is retained by a cap that permits the

the main jet into the main well.

fuel to flow out of holes in the side of the cap. The design of the fuel

An angular connecting idle well intersects the main well. An idle

bowl eliminates the need for a fuel baffle. The fuel inlet needle is

tube Is installed in the idle well. Fuel travels into the idle well and

controlled by a dual lung nitrophyl (a closed cellular buoyant material

through the restriction into the idle tube. This metered fuel mixes with

which cannot collapse or leak) float and a stainless steel float lever

air which enters through the idle air bleed located in the fuel bowl

which is hinged by a stainless steel float shaft.

cover.

The fuel inlet system must constantly maintain the specified

At curb idle the air and fuel mixture flows down the idle channel

level of fuel as the basic fuel metering systems are calibrated to

and is further mixed or broken up by air entering the Idle channel

deliver the proper mixture only when the fuel is at this level. When the

through the transfer slot which is above the throttle valve at curb idle.

fuel level in the bowl drops, the float also drops permitting additional

During low speed operation the throttle valve moves, exposing

fuel to flow past the fuel inlet needle into the bowl.

the transfer slot to manifold vacuum and fuel begins to flow through

The float chamber is vented internally into the air horn. At idle

the transfer slot as well as the idle port. As the throttle valve is opened

speed the float may be vented externally to the fuel canister.

further .d engine speed increases. the air flow through the carburetor

also increases.

This increased air flow creates a vacuum or

depression in the venturi and booster nozzle and the main metering

system begins to discharge air and fuel.