Basic Engine

pump before the oil enters the engine. A valve, integral

A pressure lubrication system is maintained by a rotor

with the filter, provides a bypass to an oil gallery, if the

type oil pump mounted in the crankcase. Oil is pumped

filter should become clogged.

from the oil pan sump at the rear of the oil pan through

passages to the bearings and other engine components.

These engines are equipped with a crankcase ventilation

A spring-loaded relief valve in the pump limits the

system that vents crankcase fumes through two vented oil

maximum pressure in the system. A full-flow filter cleans

fill caps on the rocker arm cover.

the entire output of the

FIG 2 Engine Assembly

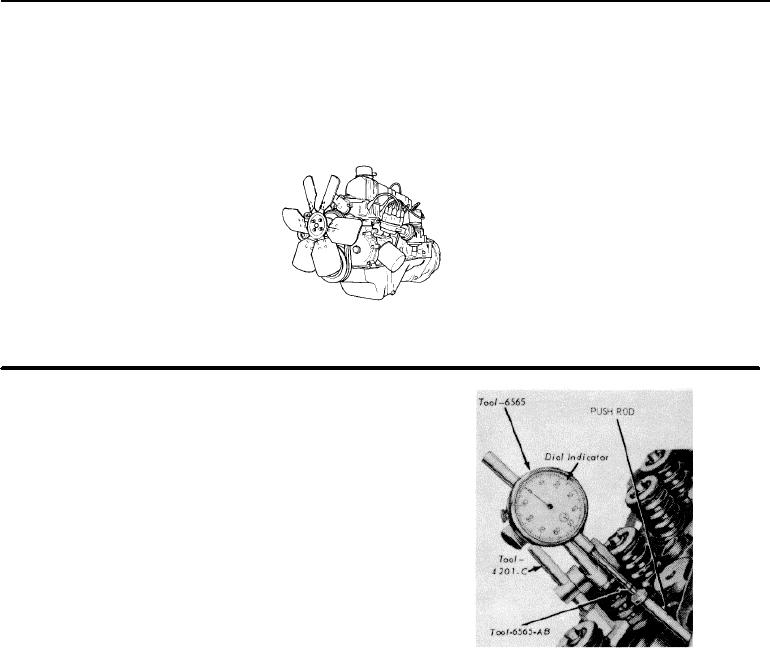

DIAGNOSIS AND TESTING CAMSHAFT LOBE LIFT

Check the lobe lift in consecutive order and make a note

of the readings.

I. Remove the air cleaner and valve rocker arm cover.

2. Remove the valve rocker arm shaft assembly as

detailed in Removal and Installation. Install a solid tappet-

type push rod in the push rod bore of the camshaft lobe to

be checked or use an adapter for ball end push rods.

3. Make sure the push rod is in the valve lifter socket.

Install a dial indicator in such a manner as to have the ball

socket adapter of the indicator on the end of the push rod

in the same plane as the push rod movement (Figure 3).

4. Connect an auxiliary starter switch in the starting circuit.

Crank the engine with the ignition switch OFF.

Bump the crankshaft over until the tappet or lifter is on the

base circle of the camshaft lobe. At this point, the push

rod will be in its lowest position.

FIG. 3 Testing Camshaft Lobe Lift Typical

5. Zero the dial indicator. Continue to rotate the crankshaft

slowly until the push rod is in the fully raised position

COMPRESSION TEST COMPRESSION GAUGE CHECK

(highest indicator reading).

6. Compare the total lift recorded on the indicator with

specifications.

1. Be sure the crankcase is at the proper level and the

7. To check the accuracy of the original indicator reading,

battery is properly charged. Operate the engine for a

continue to rotate the crankshaft until the indicator reads

minimum of 30 minutes at 1200 rpm or until the engine is

zero. If the lift on any lobte l below specified wear limits,

at normal operating temperature. Turn the ignition switch

the camshaft and the valve lifters operating on the worn

off; then remove all the spark plugs.

lobe(s) must be replaced.

8. Remove the dial indicator and auxiliary starter switch.

9. Install the rocker arm shaft assembly as detailed under

Removal and Installation.

10. Install the valve rocker arm cover and the air cleaner.

1-03