DESCRIPTION

The Revers-O-Matic Drive consists of a pair of hydraulically actuated multiple disc clutches When the front clutch is

engaged, the output shaft turns engine-wise and in most applications this produces forward motion The rear clutch is

driven by a simple gear train, and its rotation is opposite to the front clutch Therefore, when the rear clutch is engaged,

the output shaft turns anti-enginewise and in most applications this produces rearward motion.

The power Is transmitted from the engine to the Revers-O-Matic Drive through a torque converter The use of a torque

converter, has two distinct advantages First, the converter is essentially a fluid drive, there being no direct mechanical

connection through it This feature creates a very smooth and shock-free drive with the elimination of engine stalling and

lugging Secondly, the converter multiplies torque, but only during heavy pull-down loads When loads are light, the

converter transmits the engine power directly at almost engine speed and there is rno torque multiplication The net result

is an action like a transmission, with infinitely variable and automatic speed ratios The need for shifting gears, although

present, is greatly reduced.

The Revers-O-Matic Drive is controlled by (1) one of (4) four control systems

The standard control (40RC7824) is a very unique system, thus being a device that sorts out motions from a single

hand lever that FIRST engages one of the clutches and then accelerates the engine as the lever is moved further.

Therefore, it is a unified control that regulates both the direction of travel and the speed of travel Movement of the lever

from a neutral position In one direction produces forward motion, and opposite movement of the lever produces rearward

motion The optional 40RC7818 control is basically the same type as the 40RC7824 standard control, except that it is

actuated by foot pedals instead of a hand lever. The action of the foot pedal is essentially the some, except that one

pedal produces forward motion and the other, rearward motion

The optional control system (40RC7812) is designed to accommodate the system requiring a self centering control

valve, it also features the synchronized characteristic of engaging the clutches before accelerating the engine The

optional control system (40RC7804) is designed to accommodate the system requiring a 3 pos. Valve and a separate

accelerator device.

CAUTION

The clutches are not power absorbing members and must not be subjected to slippage under

power.

The clutch must be engaged prior to accelerating the engine when the vehicle Is to be moved or

direction changed.

The clutches are hydraulically applied and spring released. Each clutch has six friction plates

which have sintered bronze facings and six reaction plates of polished steel Because the

clutches are hydraulically controlled, there is automatic compensation for normal wear - no

adjustment is necessary

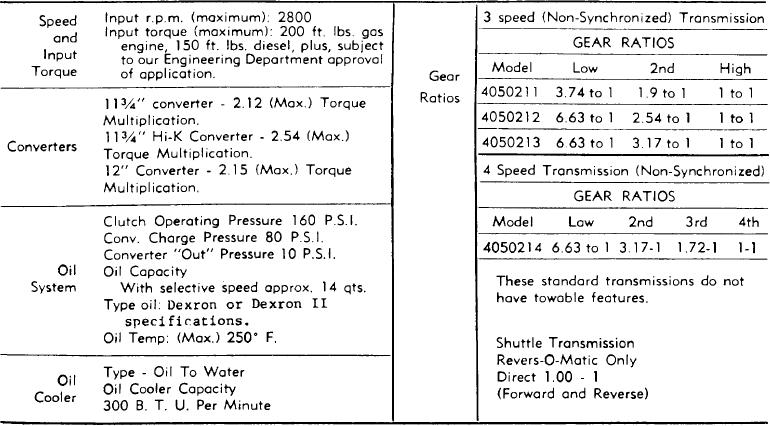

SPECIFICATIONS AND APPLICATION DATA

B-3