TM 5-3805-296-10

0010

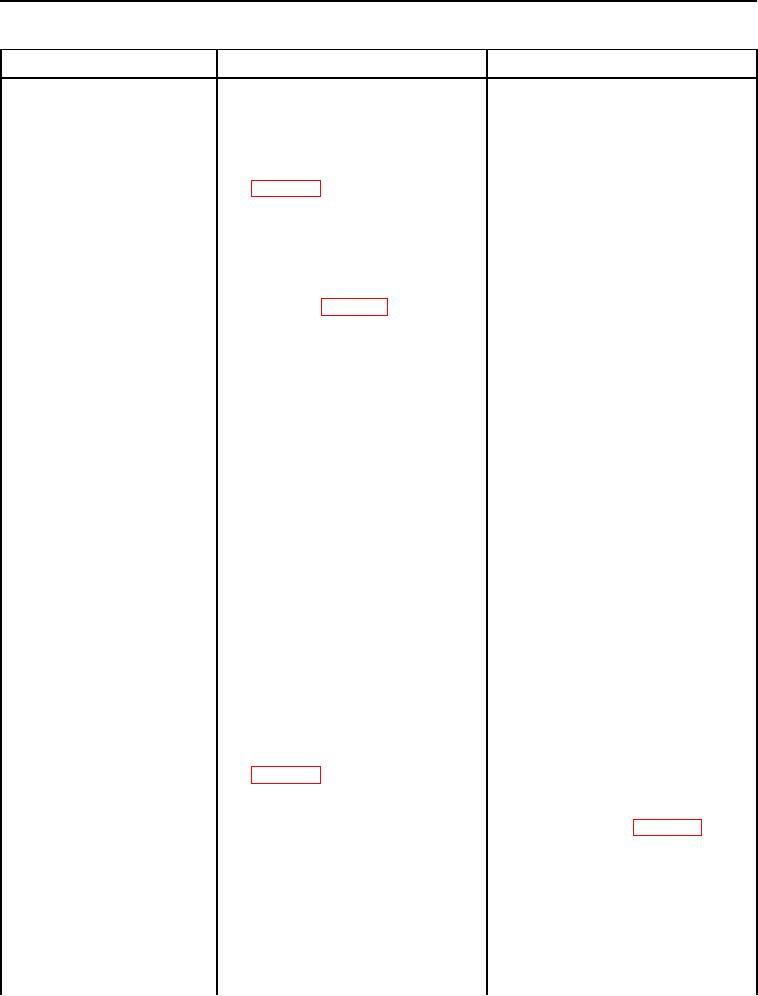

Table 1. Operator Troubleshooting - Continued.

0010

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

27. Hydraulic System Fail-

Hydraulic System Failure Indicator

ure Indicator Illumi-

Off -

nated - Continued

Troubleshooting complete.

28. Torque Converter Oil

1. Ensure proper shift lever range is

Proper Shift Lever Range Selected -

Temperature Gauge Indi-

selected for machine operation

Proceed to step 3.

cates Overheating and

Proper Shift Lever Range Not

Action Light Comes

Selected -

On (During Normal

Move shift lever to proper range.

Operation)

Proceed to step 2.

2. Verify transmission hold control is

Control Is Off -

turned off (WP 0004).

Proceed to step 3.

Control Is On -

Turn control off.

Proceed to step 3.

3. Check torque converter oil

Temperature Gauge Indicates

Normal Temperature -

temperature gauge for normal

temperature readings.

Troubleshooting complete.

Temperature Gauge Indicates

Overheating -

Proceed to step 4.

4. Reduce load and continue to

Temperature Remains in Normal

monitor temperature.

Range -

Troubleshooting complete.

Temperature Returns to Overheat

Condition -

Proceed to step 5.

5. Check for leaks.

No Leaks Found -

Proceed to step 6.

Leak(s) Found -

Proceed to step 6.

6. Check transmission oil level

Transmission Oil Level Is Correct -

Notify Field Maintenance.

Transmission Oil Level Is Low -

Add transmission oil (WP 0012).

Proceed to step 7.