TM 9-4940-568-34

7-16

7-4. CYLINDER HEAD REPAIR (CONT).

b.

Cleaning/Inspection.

(1)

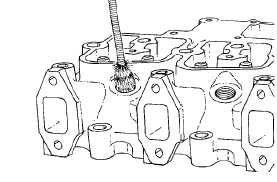

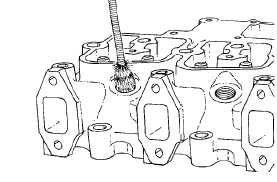

Clean carbon from injector nozzle seat with

bore brush.

Compressed air used for cleaning

purposes must not exceed 30 psi

(207 kPa). Use only with

effective chip guarding and

personal protective equipment

(goggles/shield, gloves, etc) or

injury to personnel may result.

(2)

Wash cylinder head in hot soapy water

solution and dry with compressed air.

(3)

Polish gasket surfaces with 400-grit paper.

Use sander or sanding block to maintain a

flat surface.

(4)

Inspect valve guides for scuffing or scoring.

(5)

Inspect cylinder head surface for nicks and

erosion.

(6)

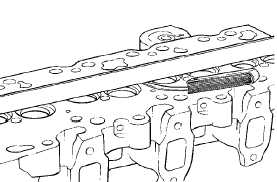

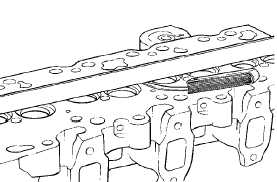

Using a feeler gage and straight edge, check

cylinder head for distortion.

The overall flatness, side to side, must not

exceed 0.003 in. (0.075 mm).

The overall flatness, end to end, must not

exceed 0.008 in. (0.203 mm).