TM 9-4940-568-34

3-20

3-6. TURNTABLE BEARING INSPECTION PROCEDURE (CONT).

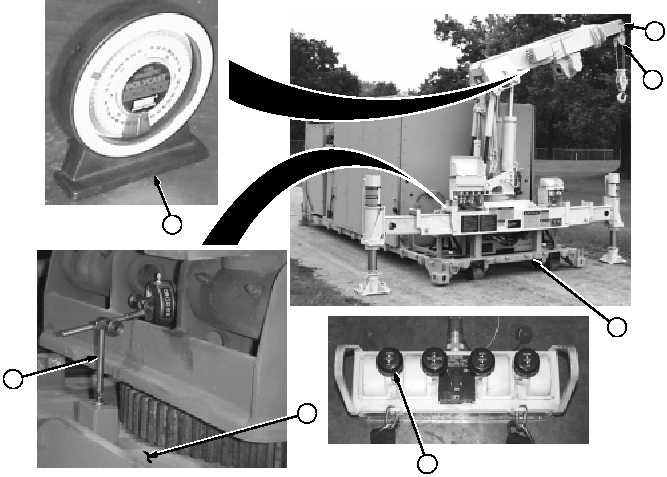

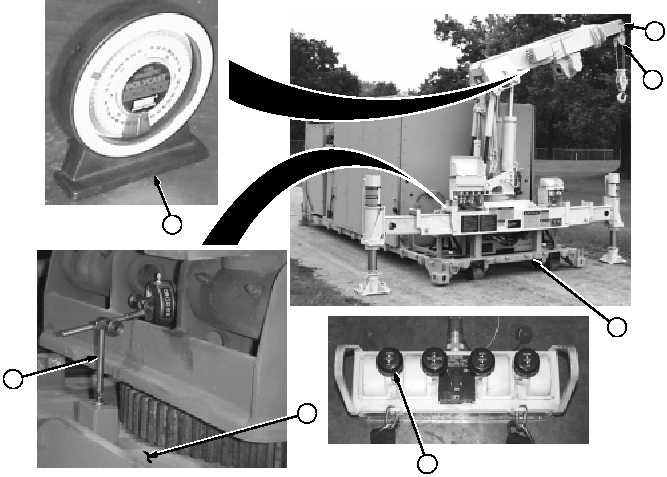

1

10

8

2

3

4

11

NOTE

Any reading equal to or over .065 in. (1.65 mm) will require a new bearing to be

ordered and installed as soon as possible. If the reading occurs on the first step of the

inspection, it is not necessary to continue the inspection. However, even if the first

reading is within the specifications, it is still necessary to complete all of the remaining

steps in the inspection procedure.

(7)

Record dial indicator reading.

(8)

If reading is equal to or over .065 in. (1.65 mm), perform bearing replacement procedures

(Para 3-29). If reading is under .065 in. (1.65 mm) continue the inspection procedure.

(9)

Rotate boom (2) 90 degrees to position boom nose (3) over right side of the FRS (4).

(10)

Lower boom (2) to obtain a level boom angle.

(11)

Position dial indicator (8) with magnetic base on subframe (11). Plunger of dial indicator must be in-line

with the axial centerline of the crane boom (2), with the plunger tip centered as close as possible above

the tip of the swing gear tooth.

(12)

Adjust dial indicator (8) to preload the dial, then zero the dial indicator.

(13)

Operate boom up control (10) until boom angle is reading 60 degrees on magnetic protractor (1).