TM 9-2610-200-14

2-46

CHAPTER 2. CARE, MAINTENANCE, AND INSPECTION (Con't)

SECTION III. UNIT MAINTENANCE (Con't)

2-29. RUNFLAT TIRE MAINTENANCE (HMMWV) (Con't).

c. ASSEMBLY (Con't)

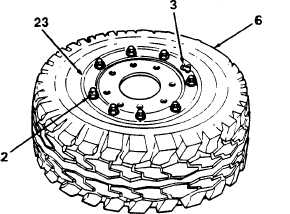

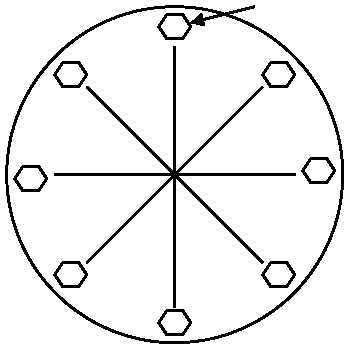

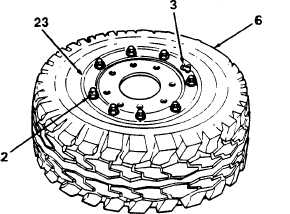

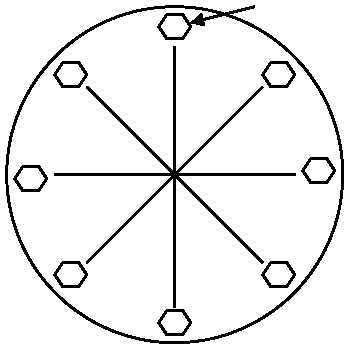

12. Torque eight self-locking nuts (1) to 65 Ib.-

ft, (88 N.m) in sequence shown.

13. Check wheel assembly for gaps at each stud

(9) between rim halves (2 and 8) .Use a 0.0015

inch (0.038 mm) thickness gage (e.g. spark plug

gap feeler gage) to detect gaps. If gaps are

detected, disassemble and assemble wheel

assembly and check for gaps. If gaps are still

detected, replace rim half (2).

14. Install valve core (4) in valve stem (3) (see

paragraph 2-26).

WARNING

Never inflate a wheel assembly without having checked wheel locknut torque's to ensure that

the wheel locknuts are tightened to specification. An assembly with improperly tightened

locknuts could separate under pressure, resulting in serious injury or death.

Always use a tire inflation safety cage when inflating tires. Stand to one side of the cage during

inflation, never directly in front. Keep hands out of cage during inflation. Inflate assembly to

recommended pressure using a pneumatic tire inflator-gage. Do not exceed 30 psi (207 kPa) cold

inflation pressure. Failure to follow these instructions may result in serious injury or death.

15. Place assembly in an inflation safety cage (see

paragraph 2-3} and inflate tire (6} to 30 psi (207

kPa) to seat tire bead.

16. Inflate tire (1) to recommended pressure (see

TM 9-2330-280-10).

17. Check for leaks around rim edges (23) and valve

stem (3) using a detergent and water solution.

FOLLOW-ON TASKS:

Install wheel (TM 9-2320-280-20).

5

8

2

3

6

7

4

1

1