TM 9-2610-200-14

D-3/(D-4 Blank)

APPENDIX D: OSHA STANDARD 29 CFR 1910.177 (Con't)

ment on or against the restraining device.

(7) After tire inflation, the tire and wheel components shall be

inspected while still within the restraining device to make

sure that they are properly seated and locked. If further

adjust- ment to the tire or wheel components is

necessary, the tire shall be deflated by removal of the

valve core before the adjustment

is made.

(8) No attempt shall be made to correct the seating of side and

lock rings by hammering, striking or forcing the components

while the tire is pressurized.

(9) Cracked, broken, bent or otherwise damaged rim com-

ponents shall not be reworked, welded, brazed, or otherwise

heated.

(10) Whenever multi-piece rim wheels are being handled,

employees shall stay out of the trajectory unless the employer

can demonstrate that performance of the servicing makes the

employee's presence in the trajectory necessary.

(11) No heat shall be applied to a multi-piece wheel or wheel

component.

(g) Safe operating procedure--single piece rim wheels. The

employer shall establish a safe operating procedure for servic-

ing single piece rim wheels and shall assure that employees

are instructed in and follow that procedure. The procedure

shall include at least the following elements:

(1) Tires shall be completely deflated by removal of the valve

core before demounting.

(2) Mounting and demounting of the tire shall be done only

from the narrow ledge side of the wheel. Care shall be taken to

avoid damaging the tire beads while mounting tires on wheels.

Tires shall be mounted only on compatible wheels of matching

bead diameter and width.

(3) Nonflammable rubber lubricant shall be applied to bead

and wheel mating surfaces before assembly of the rim wheel,

unless the tire or wheel manufacturer recommends against the

use of any rubber lubricant.

(4) If a tire changing machine is used, the tire shall be inflat-

ed only to the minimum pressure necessary to force the tire

bead onto the rim ledge while on the tire changing machine.

(5) If a bead expander is used, it shall be removed before the

valve core is installed and as soon as the rim wheel becomes

airtight (the tire bead slips onto the bead seat).

(6) Tires may be inflated only when contained within a

restraining device, positioned behind a barrier or bolted on the

vehicle with the lug nuts fully tightened.

(7) Tires shall not be inflated when any flat, solid surface is in

the trajectory and within one foot of the sidewall.

(8) Employees shall stay out of the trajectory when inflating a

tire.

(9) Tires shall not be inflated to more than the inflation pressure

stamped in the sidewall unless a higher pressure is recommended

by the manufacturer.

(10) Tires shall not be inflated above the maximum pressure

recommended by the manufacturer to seat the tire bead firmly

against the rim flange.

(11) No heat shall be applied to a single piece wheel.

(12) Cracked, broken, bent, or otherwise damaged wheels shall

not be reworked, welded, brazed, or otherwise heated.

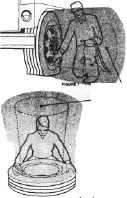

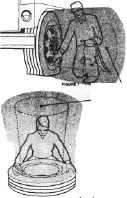

OSHA APPENDIX A

TRAJECTORY

WARNING

STAY OUT OF

THE TRAJECTORY AS

INDICATED BY SHADED

AREA

Note: Under some circumstances,

the trajectory may

deviate

from the expected path.

Appendix B-Ordering Information for the OSHA

Charts OSHA has printed two charts entitled

"Demounting and

Mounting Procedures for Truck/Bus Tires" and "Multi-

piece Rim Matching Chart," as part of a continuing

campaign to reduce accidents among employees who

service large vehicle rim wheels.

Reprints of the charts are available through the

Occupational Safety and Health Administration (OSHA)

Area and Regional Offices. The address and telephone

number of the nearest OSHA office can be obtained by

looking in the local telephone directory under U.S.

Government, U.S. Department of Labor, Occupational

Safety and Health Administration. Single copies are

available without charge.

Individuals, establishments and other organizations

desiring single or multiple copies of these charts may

order them from the OSHA Publications Office, U.S.

Department of Labor, Room N-3101, Washington, DC

20210. Telephone (202) 219-4667.

TRAJECTORY