TM 9-2610-200-14

2-102

CHAPTER 2. CARE, MAINTENANCE, AND INSPECTION (Con't)

SECTION V. GENERAL SUPPORT MAINTENANCE (Con't)

2-45. INSPECTION OF REPAIRED OR RETREADED TIRES.

a. GENERAL.

All incoming shipments of retreaded and repaired tires must be examined to verify satisfactory

workmanship and to ensure that only dependable, safe retreaded tires are accepted and used. The

following instructions provide standard criteria for acceptance inspection of retreaded or repaired tires.

Any of the defects listed below are cause for rejection of tires.

b. MARKINGS.

(1) Retread identification markings missing or not legible (not applicable to Group 4, Off Road,

Low Speed Tires, Industrial Tires and Agricultural Tires).

NOTE

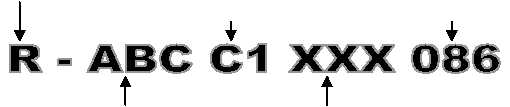

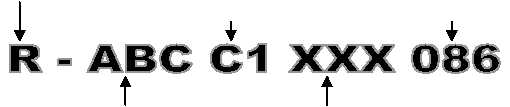

Each tire will be permanently marked with the contractor/vendor's identification

mark, the week and year of retread, and a number or name indicating the type of

retreading performed. The DOT Code identification and the date of manufacture

shall conform to the requirements of Section 574.5 of the Department of

Transportation Tire Identification and Record Keeping procedures. When the type of

retreading is indicated by a number, the number shall be as specified in the table

Inspection Marking Codes. For example, a full bead-to-bead retread shall be marked

I-A, a top (shoulder to shoulder) retread 1-B, etc. The number or name shall also be

molded into the tread shoulder area of the tire as prescribed above. Marking symbols

shall not be less than 5/32 inch (4.0 mm) in height and not more than a 2 inch space

between symbols.

(2) Nail hole repairs (Type II-A) are exempt from the permanent marking. When tires are

retreaded in a plant other than the contractor's own facility, the subcontractor will comply with the

requirements set

RETREAD TIRE SIZE OR CURRING

DATE OF

MATRIX CODE RETREAD

RETREAD GROUP OF

PLANT CODE OPTIONAL CODES

EXAMPLE OF RETREAD DOT CODE FOR RETREAD TIRES