TM 9-2610-200-14

2-66

CHAPTER 2. CARE, MAINTENANCE, AND INSPECTION (Con't)

SECTION IV. DIRECT SUPPORT MAINTENANCE (Con't)

2-36. DEMOUNTABLE FLAT BASE RIM WITH TUBELESS TIRE MAINTENANCE.

This Task Covers:

a. Demounting

b. Mounting

Initial Setup:

Materials/Parts:

Tire and rim lubricant (Item 90, Appendix C)

Preformed Packing (refer to the vehicle parts

manual)

Tools/Test Equipment:

Inflator-gage, pneumatic tire (includes 10'

hose) (Item 30, Appendix B)

Tire iron, curved flat type (Item 34,

Appendix B)

Tire iron, curved bead breaker type (Item

33, Appendix B)

Tire iron, lockring type (Item 35,

Appendix B)

a. DEMOUNTING

1. Remove valve core and completely deflate tire (see paragraph 2-26). Run a piece of wire through

valve stem to ensure that it is not plugged.

WARNING

When dislodging tire beads, lockring, or side ring flanges, be absolutely certain that

no air pressure remains in tire. Serious injury or death could result.

CAUTION

Use tire and rim lubricant as necessary to avoid damaging tire beads or bead seats

during demounting and mounting.

CAUTION

Never use petroleum based products such as oil or grease when demounting/mounting tires

from rims. Petroleum based products have a

severe degrading affect on tire rubber. Use only

approved tire and rim lubricant.

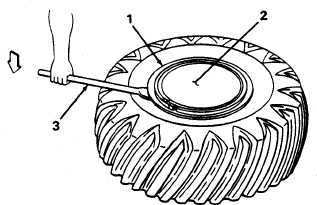

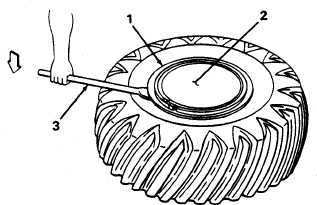

2. Loosen outer tire bead from demountable side ring

flange (1) by inserting a curved bead breaker tire

iron (3) between tire bead and side ring flange.

3. Work progressively around rim (2) rotating curved

bead breaker tire iron (3) down until outer tire

bead is completely free of side ring flange (1).