TM 9-2610-200-14

2-65

CHAPTER 2. CARE, MAINTENANCE, AND INSPECTION (Con't)

SECTION IV. DIRECT SUPPORT MAINTENANCE (Con't)

2-35. NONDEMOUNTABLE FLAT BASE RIM TIRE MAINTENANCE (Con't).

WARNING

When inflating tires mounted on the vehicle, personnel must remain a minimum of 10 ft (3.1

m) away from tire and not in possible path of lockring or rim flange trajectory in the event

of rim separation. Should components fly off, serious injury or death could result.

Never inflate tires over 40 psi (276 kPa) to seat tire beads. If beads do not seat, deflate,

demount, and check the tire/rim match. Mount and lubricate according to instructions.

Serious injury or death could result if these procedures are not followed.

When inflating tires on nondemountable rims, always use a pneumatic tire inflator-gage and

10 ft. (3.1 mm) air hose. Failure to do so could result in serious injury.

16. Install valve core (see paragraph 2-26).

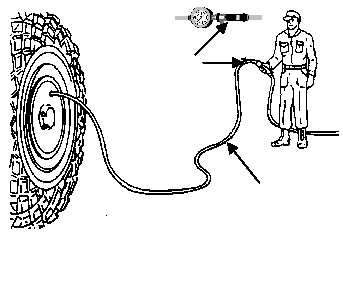

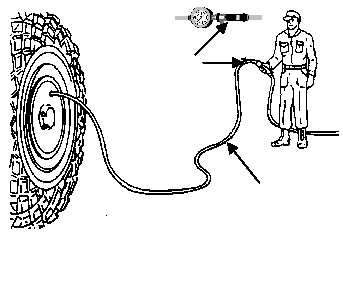

17. Using a pneumatic tire hose (13) with in-line inflator-gage (12), stay out of the danger area and inflate

tire to a maximum of 15 psi (103 kPa) and then allow tire to completely deflate. This will allow tube

to center in tire.

18. Inflate the tire enough to seat both tire

beads. Both tire beads should seat

properly before reaching 40 psi (276

kPa). If tire beads fail to seat, deflate tire,

determine cause of failure, take corrective

action, add additional tire and rim

lubricant and repeat this step.

19. Visually inspect all rim components to

ensure that they are properly seated and

allow tire to deflate.

20. Inflate tire to normal operating pressure

(see appropriate vehicle TM). Visually

inspect rim components to ensure that

they are properly seated.

21. Install valve cap on valve stem finger-

tight.

22. Lower jack and remove from under vehicle (see appropriate vehicle TM).

12

13