TM 9-2330-359-14&P

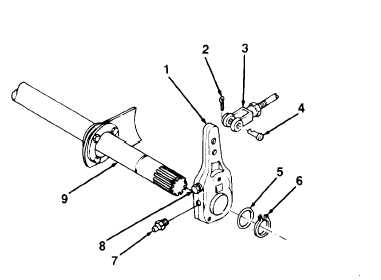

4-34. SLACK ADJUSTER REPLACEMENT.

This Task Covers:

a.

Removal

c.

Installation

b.

Cleaning and Inspection

Initial Setup:

Equipment Conditions:

Materials/Parts:

l Wheels chocked.

l One cotter pin

Tools/Test Equipment:

l One retaining ring

l General mechanic’s tool kit

c Retaining ring pliers

1.

2.

Remove cotter pin (2), clevis pin (4), and discon-

nect clevis assembly (3) from slack adjuster (1).

Discard cotter pin.

NOTE

M872 and M872A2 have no washer.

Remove retaining ring (6), washer (5), and slack

adjuster (1) from camshaft (9). Remove lubrication

fitting (7) from slack adjuster. Discard retaining

ring.

b. CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, Is toxic and flammable. Always wear protective goggles

and gloves, and use only In a well-ventilated area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO NOT use near open flame or excessive heat.

The solvent’s flash point Is 100°F-138°F (38°C-59°C). If you become dizzy while

using cleaning solvent, Immediately get fresh air and medical help. If solvent contacts

eyes, immediately wash your eyes and get medical aid.

1.

Clean all parts with dry cleaning solvent. Allow to dry.

2.

Inspect parts for damage. Replace any damaged parts.

TA508027

4-54