2-10

Ignition System

2-10

The breaker point assembly consists of the stationary point

CLEANING AND INSPECTION

bracket assembly, breaker arm and the primary wire terminal.

SPARK PLUGS

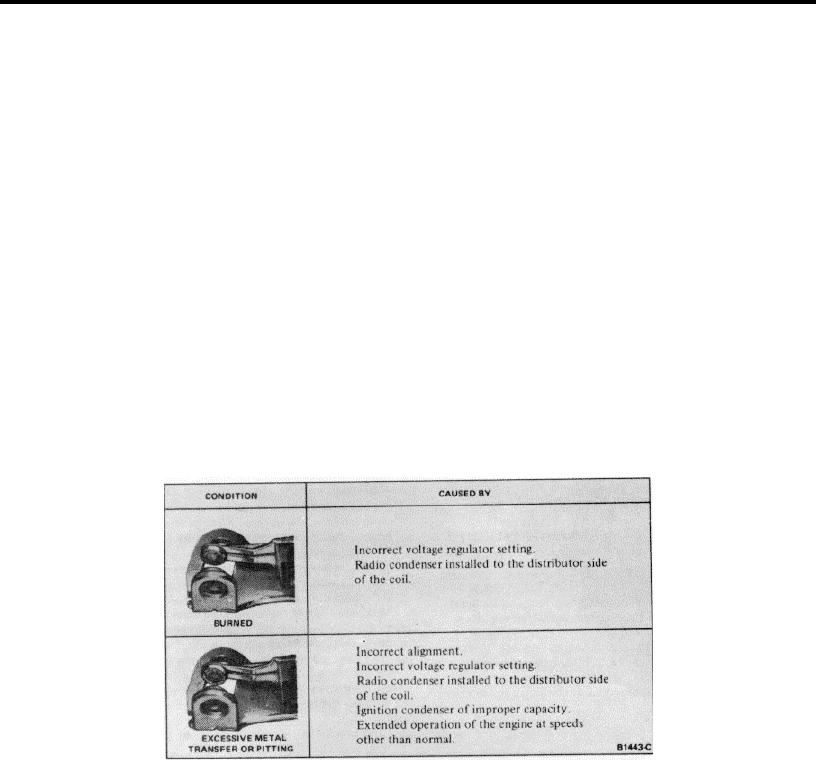

Breaker points should be inspected, cleaned and adjusted as

Examine the firing ends of the spark plugs, noting the type of

necessary. Breaker points can be cleaned with chloroform and a stiff

deposits and the degree of electrode erosion. Refer to Figure 16 for

bristle brush. Replace the breaker point assembly if the contacts are

the various types of spark plug fouling and their causes.

badly burned or excessive metal transfer between the points is evident

Clean the plugs on a sand blast cleaner, following the

(Figure 17). Metal transfer is considered excessive when it equals or

manufacturer's instructions. Do not prolong the use of the abrasive

exceeds the gap setting.

blast as it will erode the insulator and electrodes.

After cleaning, examine the plug carefully for cracked or broken

insulators, badly pitted electrodes, and other signs of malfunction.

Replace as required.

Distributor Cap

Clean the distributor cap with a soft bristle brush and mild

DISTRIBUTOR

cleaning solvent or mineral spirits. Dry the cap with compressed air.

Soak all parts of the distributor assembly (except the condenser,

Inspect the cap for cracks, burned contacts, permanent carbon tracks

breaker point assembly, lubricating wick, vacuum diaphragm,

or dirt or corrosion in the sockets. Replace the cap if it is damaged as

distributor base oil seal and electrical wiring) in a mild cleaning solvent

above.

or mineral spirits. Do not use a harsh cleaning solution. Wipe all parts

that cannot be immersed in a solvent with a clean dry cloth.

Rotor

After foreign deposits have been loosened by soaking, scrub the

Clean the rotor with a soft bristle brush and mild cleaning solvent

parts with a soft bristle brush. Do not use a wire brush, file, or other

or mineral spirits. Dry the rotor with compressed air. Inspect the rotor

abrasive object. Dry the parts with compressed air.

for cracks or burning. Replace the rotor if it is cracked or burned.

Inspect the distributor cam lobes for scoring and signs of wear.

If any lobe is scored or worn, replace the cam assembly.

Secondary Wiring

Inspect the breaker plate assembly for signs of distortion.

Wipe the wires with a damp cloth and check for breaks or

Replace the breaker plate assembly If it is distorted.

cracked insulation. Inspect the terminals and weatherseals for

Inspect all electrical wiring for fraying, breaks, etc. and replace

looseness or corrosion. Replace any wires that are not in good

any that are not in good condition.

condition.

Check the distributor base for cracks or other damage.

Check the diaphragm housing. bracket, and rod for damage.

Coil

Test the vacuum hose connections, case and diaphragm for leakage

Wipe the coil with a damp cloth and check for any cracks or

as explained under Distributor Tests. Replace all damaged parts.

other damage.

FIG. 17. Breaker Point Inspection