TM 5-3820-245-14&P

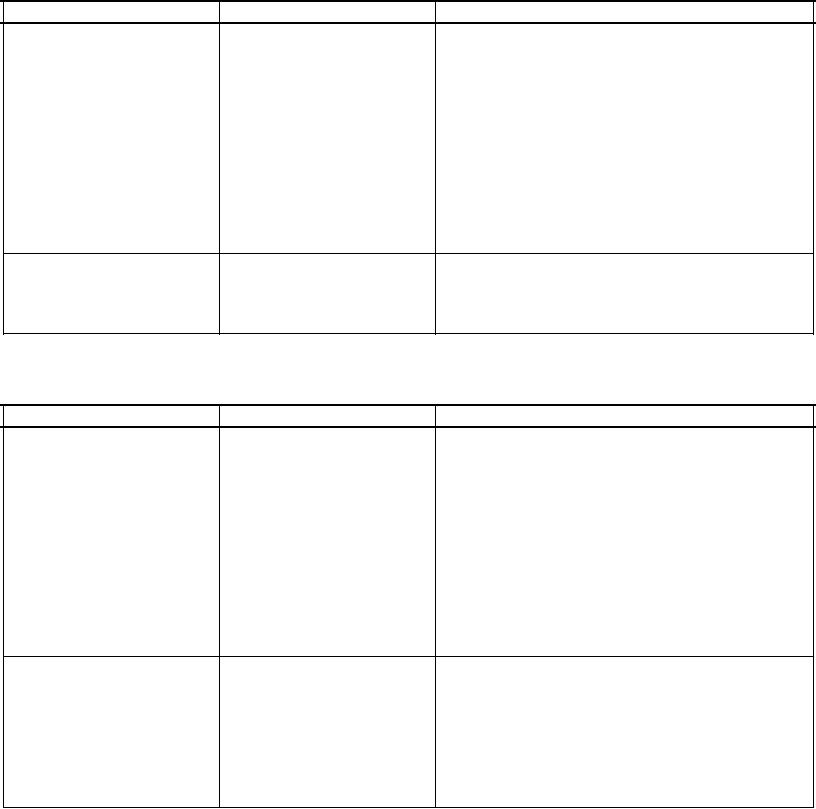

5-4. OPERATIONAL CYLINDERS TROUBLE SHOOTING (Continued)

CONDITION

PROBABLE CAUSE

REMEDY

Hydraulic oil

Normal packing wear.

Remove cable from sheave on

escaping from

top of polesetter extension.

polesetter

Disconnect both 12 inch

extension.

hydraulic hoses from bottom of

6 foot extension; pull forward

until gland is exposed. Tighten

packing gland nuts equal amount,

or until hydraulic flow is

sealed off. If adjustment has

been completely taken up,

repack using Chevron type

packing.

Leveling cylinder

Flow control valve

Adjust flow control valve

too slow or too fast.

not properly adjusted

mounted in lower port of

leveling cylinder.

5-5. DRIVE ASSEMBLY TROUBLE SHOOTING

CONDITION

PROBABLE CAUSE

REMEDY

Kelly bar will not

Damage to ring gear

Disassemble final drive at

rotate. and pinion assembly.

retainer rings on intermediate

housing. Slide final drive

assembly out until pinion

drive is free. Rotate pinion

assembly if kelly bar does not

turn. Damage is in final

drive assembly. Disassemble

according to disassembly pro-

cedure for final drive. Always

use ring gear and pinion

furnished by Reedrill, Inc.

Trouble not

A. Ring gear and

If key is not damaged, check

located in

pinion. Right

pinion teeth. Check ring gear

final drive.

angle drive.

teeth by rotating ring gear

carrier assembly and inspect

teeth through the pinion

carrier opening on right angle

housing.

PAGE 56