TM 5-3820-245-14&P

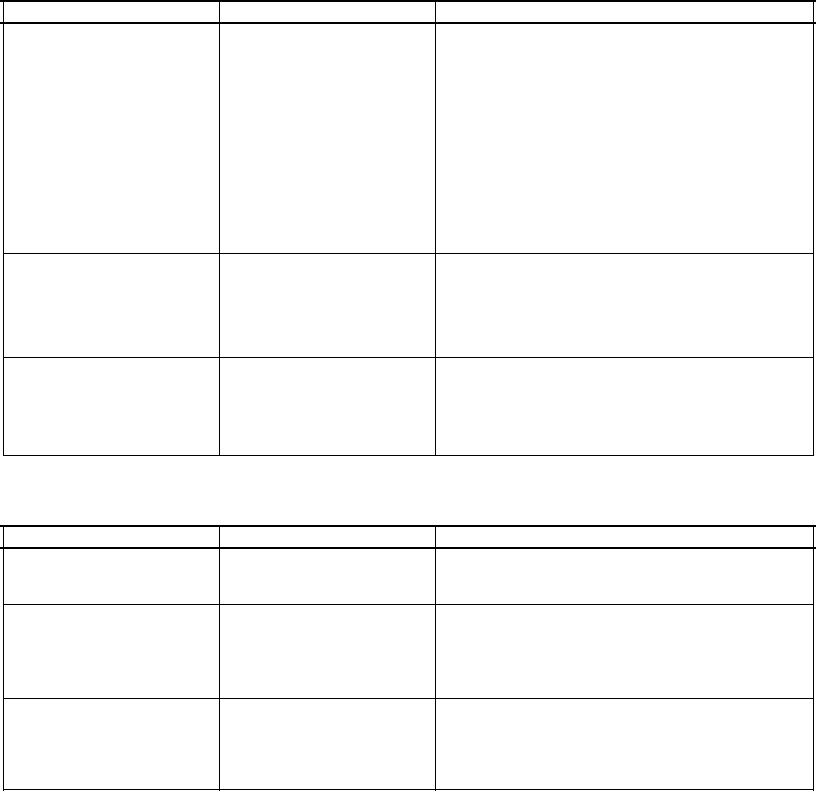

5-3. FEED RAM ASSEMBLY TROUBLE SHOOTING (Continued)

CONDITION

PROBABLE CAUSE

REMEDY

Excessive whipping

Bent kelly bar.

Upon encountering this condi-

of kelly bar while

tion, immediately shut down

digging.

operation. With kelly bar

fully extended, locate bend

in kelly bar. If bow is more

than 4 feet from the drive,

the bar can be straightened

in the machine. If the bend

has occurred above 4 feet, the

bar must be removed from the

machine. Refer to feed ram

disassembly procedure.

Bar will extend

Piston assembly.

Rings have failed on pistons.

but not retract.

Refer to feed ram disassembly

procedure. Before assembling

check feed ram cylinder for

damage.

Too much time

Flow control valve

Adjust valve mounted in line

lapse when bar

not properly

to the bottom of the feed ram.

reaches bottom of

adjusted.

Screw in to increase bar speed

hole.

and out to decrease bar speed.

5-4. OPERATIONAL CYLINDERS TROUBLE SHOOTING

CONDITION

PROBABLE CAUSE

REMEDY

Leakage around

Normal packing wear.

Tighten adjusting nut on pack-

shafts.

ing glands equal amount.

Hydraulic cylinder

Worn piston packing.

Disassemble cylinders and re-

will not hold.

pack. All cylinders except

feed ram cylinder use 1/4"

Belmont packing.

Leakage around

Loose cylinder cap.

Remove from digger and dis-

thread.

assemble checking threads for

damage. Reassemble using

nylon ribbon tape sealer.

PAGE 55