TM 5-3820-245-14&P

5-5. DRIVE ASSEMBLY TROUBLE SHOOTING (Continued)

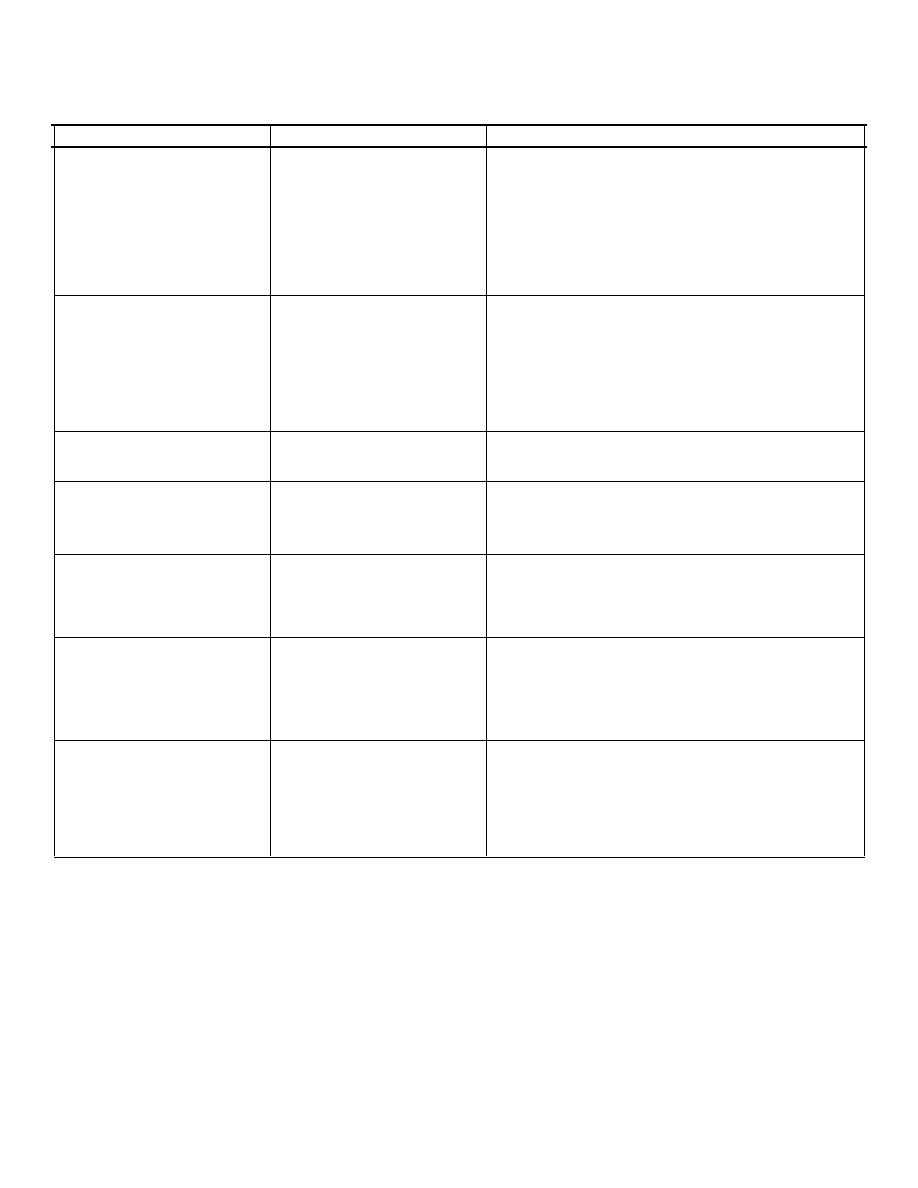

CONDITION

PROBABLE CAUSE

REMEDY

B. Ring gear output

Check ring gear carrier for

drive.

weld failure on the internal

spline assembly for excessive

wear in the internal spline.

If worn or cracked, replace

with complete new carrier

assembly.

Kelly bar will not

A. Clutch slipping.

Refer to clutch section.

rotate.

B. Drive line.

Check weld on drive line

assembly. If weld has failed,

remove drive line from digger;

realign in lathe and reweld

using AWS-ASTM-E6010 rod.

Kelly bar will not

Torque converter.

Refer to torque converter

rotate under load.

section 5-2

Housing running

Bearing failure.

Disassemble housing and

extremely hot.

replace with original equip-

ment replacement bearing.

Gear grease leak

Grease seal.

Remove drive line and

at pinion carrier

companion flange. Replace

assembly right

seal.

angle.

Gear grease leak-

Gasket

Refer to right angle assembly

ing between right

procedure for replacement.

angle housing and

intermediate

housing.

Gear grease leak-

Packing.

Replace packing on inner face

ing between inter-

of final drive flange.

mediate ring and

final drive

housing.

PAGE 57