TM 5-3820-245-14&P

5-1

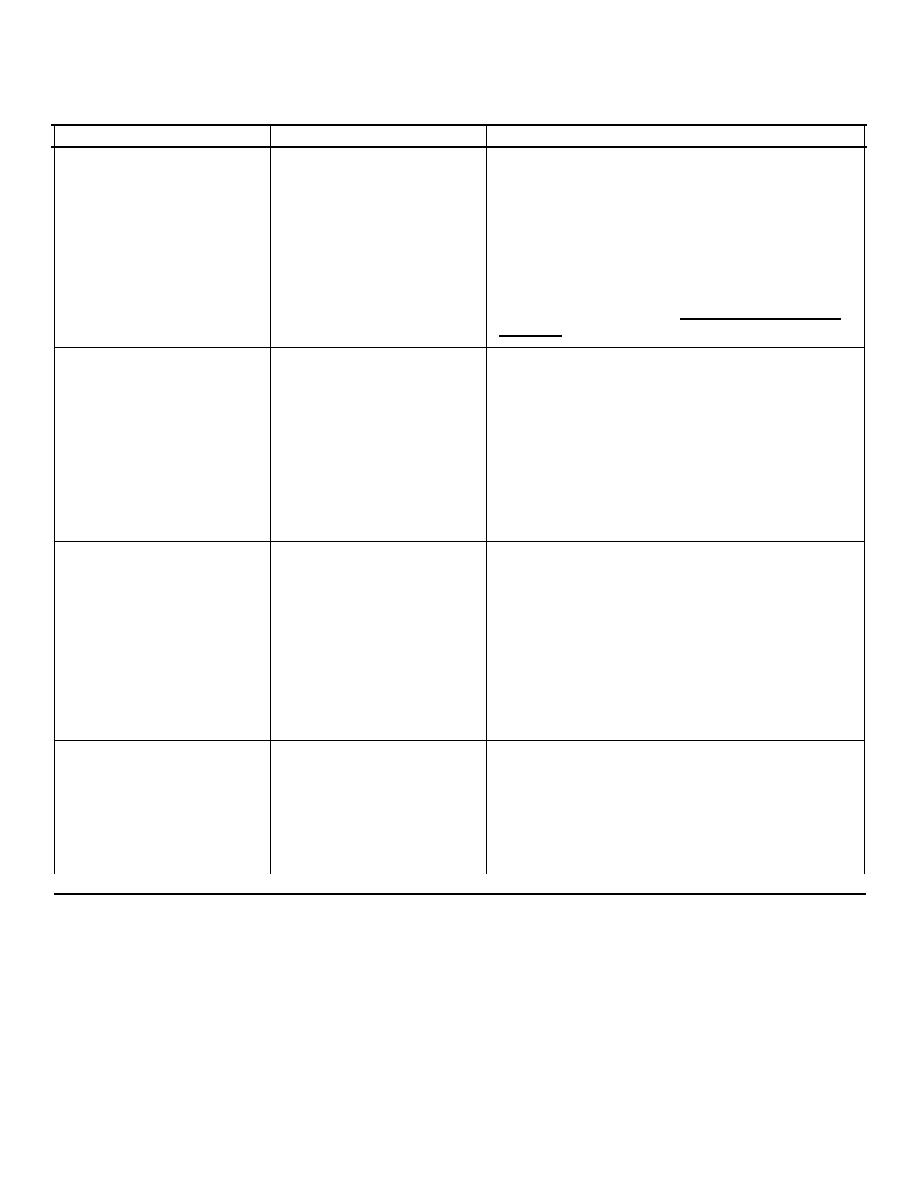

HYDRAULIC SYSTEM TROUBLE SHOOTING (Continued)

CONDITION

PROBABLE CAUSE

REMEDY

Pressure drop

Relief valve

The system is equipped with

from original

spring relaxed

single bank of valves.

pressure

or normal loss

Loosen jam nut on inlet

setting on the

of flow due to

section and turn adjustment

machine.

pump wear.

screw clockwise until the original pressure setting is

reached. If unable to raise pressure by adjusting relief

valve, the pump is badly worn and should be

replaced. Check exploded views for proper machine

model and pump number. PROPER RESSURE IS

1450 PSI.

Noisy pump

A. Oil supply low.

Fill reservoir check with

caused by

dipstick.

B. Oil too heavy.

Change to proper oil. See Lubrication Chart.

C. Oil filter

Install new filter.

plugged.

D. Suction line

Clean strainer.

strainer plugged.

Oil heating.

A. Oil supply low.

Fill reservoir. See Lubrication Chart.

B. Contaminated oil.

Drain reservoir and refill with clean oil.

C. Setting of relief

Set to correct pressure.

valves too high

or too low.

D. Oil in system too

Drain reservoir and refill

light.

with proper viscosity oil.

Shaft seal

A. Worn shaft seal.

Replace shaft seal.

leakage.

B. Broken molded V

If replacing the shaft does

seal or gasket.

not stop leakage, the pump

Bearing out of

should be disassembled and

position. Excessive

checked for worn parts.

internal wear.

PAGE 46