TM 5-3805-296-10

0012

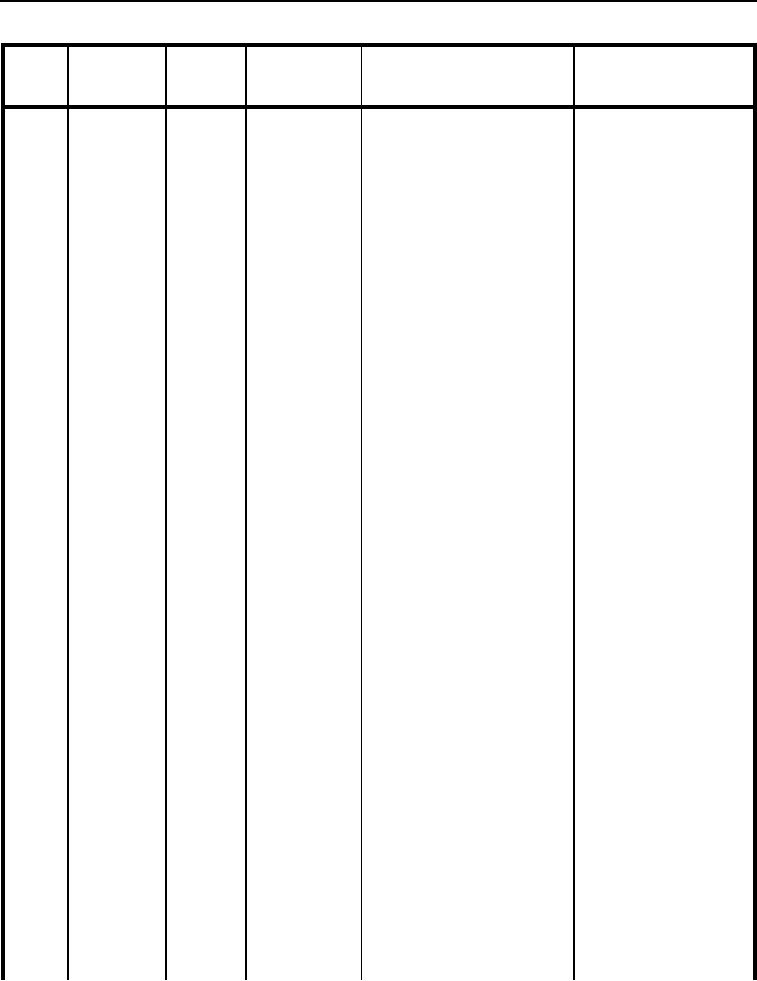

Table 1. Preventive Maintenance Checks and Services (PMCS) Continued.

ITEM TO BE

CHECKED OR

EQUIPMENT NOT

ITEM

MAN-

SERVICED

PROCEDURE

READY/AVAILABLE IF:

NO.

INTERVAL

HOURS

57

After

Draft Frame,

a. Check hydraulic lines and

Class III hydraulic leaks

Scraper Bowl,

hoses and air lines along right

or any air leak is evident.

Apron, and

draft frame for damage or

Loose or missing

Ejector

signs of leaking and secure

mounting hardware is

mounting.

noted.

b. Check electrical wiring and

Wires or connectors are

connectors for damage and

damaged.

secure mounting.

c. Check right bowl lift

Class III leaks are

cylinders, hoses, lines, and

evident. Loose or missing

fittings for damage or signs of

mounting hardware is

leaking and secure mounting.

noted.

d. Visually check bowl cutting

Damage that would

edge and right side router bit

impair operation is

for damage and loose or

evident. Cutting edge

missing mounting hardware.

worn sufficiently to allow

damage to base edge.

e. Check apron for damage

Damage that would

or obstructions.

impair operation is

evident.

f. Check for damage or

Damage that would

obstructions inside bowl.

impair operation is

evident.

58

After

.2

Transmission/

Perform hot check of

Class III leaks are

Differential Oil

transmission and differential

evident.

Level

oil levels:

a. Lift and remove cover plate

from machine.

b. Clean area around sight

gauges and fill caps.

c. Maintain oil levels between

the marks on sight gauges.

d. Remove filler cap(s).

e. Add oil as required through

filler opening(s). Refer to LO

5-3805-296-13 for proper

oil(s) based on outside

temperature. Do NOT overfill.

f. Clean filler cap(s), then

reinstall.

g. Reinstall cover plate.

0012-46