TM 9-2610-200-14

2-119

VISUAL GUIDE FOR INSPECTION AND CLASSIFICATION OF TIRES

(Con't)

2-51. RETREAD CONDITIONS (Con't).

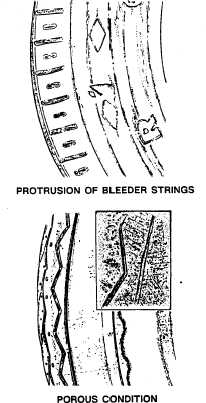

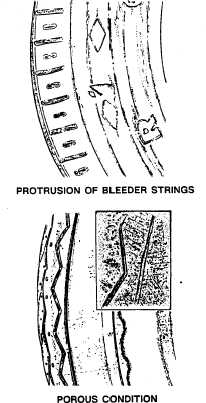

j. Vent String Protruding. Vent or bleeder strings are sometimes put into a tire to vent off air

during the molding operation. The protruding string, as shown in the example on the top right, causes no

harm, but should be clipped off flush to the tire surface.

k. Spongy (Porous) Cure. This condition is caused by an

unacceptable combination of pressure, temperature, and time

during the curing process. The spongy, porous condition is more

apparent when a thin layer is cut from the tire, as shown in the

insert.

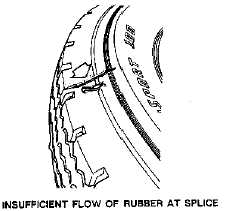

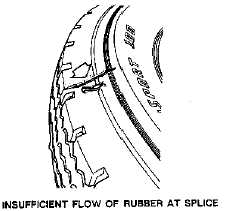

l. Improper Rubber Flow at Splice. The illustration below

shows improper buildup prior to retread molding and should be

returned to the retreader for rework.

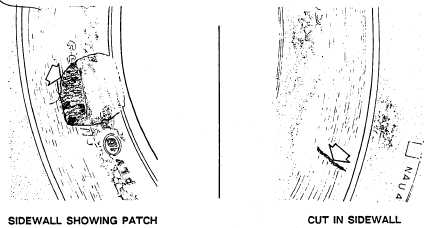

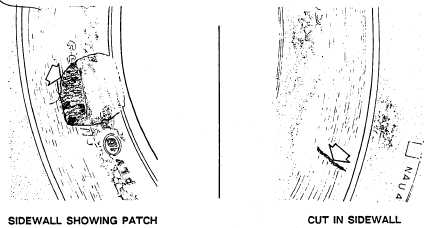

m. Improper Spot Repair. The repair, below and to the left, is too close to the bead on the tire

should have deemed non-repairable by the inspector or the retreader.

n. Cut in Sidewall. This defect, below on the right, is not readily spotted by the retreader but should

have been.